The transition to renewable energy sources is accelerating, and hydrogen is poised to play a pivotal role. With its potential as a clean fuel and energy carrier, hydrogen production from renewable sources is gaining significant attention. This article explores the innovative concept of offshore hydrogen production platforms, offering a solution for efficient and safe hydrogen generation at sea.

The Need for Offshore Hydrogen Production

Offshore wind power generation is rapidly expanding, providing a vast renewable energy resource. Combining offshore wind farms with hydrogen production facilities presents an attractive opportunity to harness this energy efficiently. The hydrogen produced offshore can be stored, transported, or utilized for various purposes, contributing to a greener energy landscape.

Offshore Hydrogen Production Platform Design

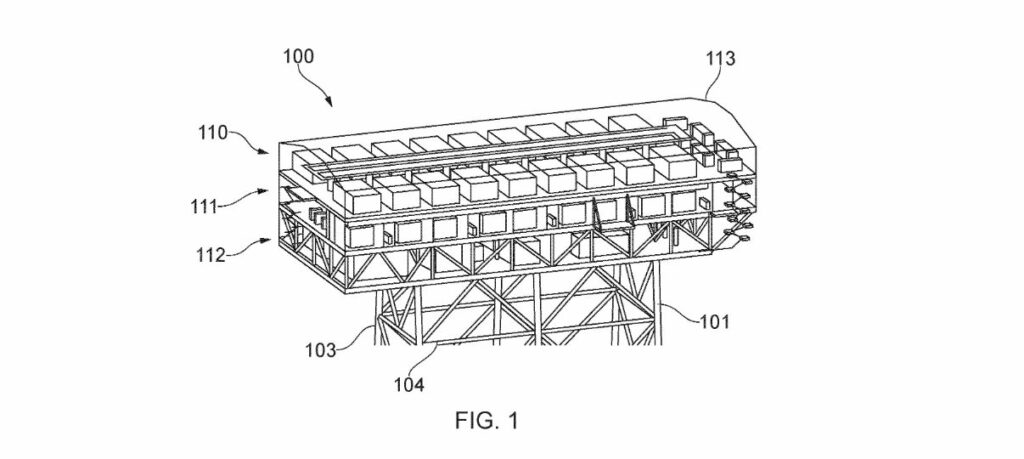

An offshore hydrogen production platform is designed to safely and efficiently produce hydrogen at sea. It typically consists of a support structure, multiple vertically spaced decks, and hydrogen production equipment on the uppermost deck. This equipment, such as a water electrolysis plant, is housed within an enclosure for safety and environmental protection.

Key Design Features:

- Vertically Spaced Decks: This configuration optimizes space utilization, simplifies installation and maintenance, and facilitates equipment segregation for improved safety.

- Enclosure: Encapsulating the hydrogen production equipment ensures effective containment and minimizes the risk of accidental hydrogen releases.

- Ventilation Systems: Passive or forced ventilation systems control the enclosure’s temperature, humidity, and air quality.

- Water Purification Plant: A desalination plant or process water supply pipeline provides the necessary water for hydrogen production via electrolysis.

- Cooling System: An open or closed-loop cooling system ensures efficient heat management during electrolysis.

- Electrical and Instrumentation Deck: Houses batteries, rectifiers, transformers, control systems, and telecommunications equipment.

- Unmanned Operation: Remote operation capability enhances safety and reduces operational costs.

- Power Source: The platform can be powered by an external electrical grid or renewable sources like solar panels and wind turbines, increasing its sustainability.

The Hydrogen Production Process

Water electrolysis is a common method used in offshore hydrogen production. The process involves using electricity to split water into hydrogen and oxygen. The hydrogen produced is then processed, compressed, and stored or transported for further use.

Advantages of Offshore Hydrogen Production

- Access to abundant renewable energy: Offshore locations offer consistent wind and solar resources for clean hydrogen production.

- Reduced land use constraints: Offshore platforms minimize competition for land resources.

- Proximity to energy demand: Offshore hydrogen production can be located near coastal industrial areas or hydrogen transport infrastructure.

- Scalability: Modular design allows for capacity expansion as hydrogen demand grows.

Offshore hydrogen production platforms represent a promising avenue for sustainable hydrogen production. These innovative platforms leverage the vast potential of offshore renewable energy sources, contributing to a cleaner and more secure energy future. As the world transitions toward a hydrogen economy, offshore hydrogen production is set to play a vital role in meeting the growing demand for this versatile energy carrier.