Ammonia has long been recognized not just for its utility as a fertilizer component but also for its potential as a fuel. However, efficient and safe combustion of ammonia presents various challenges.

In response, a novel device has been patented to enhance the combustion process, making it more reliable, environmentally friendly, and safe. This patent could pave the way for significant advancements in both heating technology and ammonia decomposition processes.

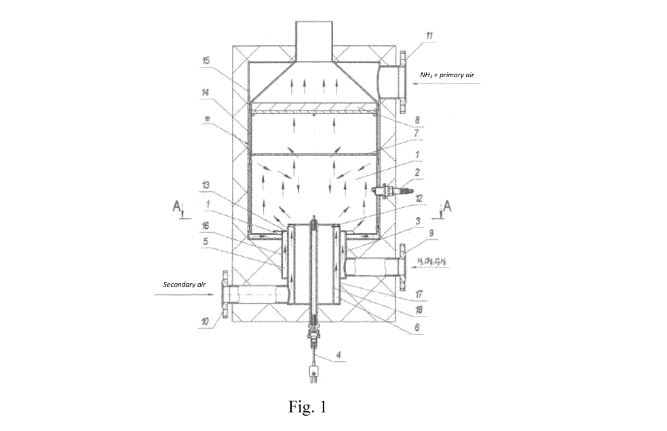

At the core of this invention is a device specifically designed for combusting ammonia. The design includes a cylindrical combustion chamber, which is essential for the controlled mixing and burning of the air-ammonia mixture. The device is not limited to any single function—it is versatile enough to be used in heating devices for producing heat and devices aimed at decomposing ammonia to create a nitrogen-hydrogen mixture.

Key Components and Features

The device is composed of several notable components: a cylindrical body that contains the combustion chamber and a system for supplying the air-ammonia mixture. At the outlet of the main supply channel, a tangential swirler is placed, which aids in the efficient mixing of ammonia with air. Additionally, a spark plug is strategically installed within the chamber to initiate combustion.

To support the main process, an additional annular channel is provided for heating and further introducing the air-ammonia mixture. This feature ensures that the mixture is in optimal condition prior to combustion. Innovations such as through holes for installing components like the spark plug, flame sensor, and flame stabilizer make the device more sophisticated and adaptable.

Safety and Environmental Considerations

One of the highlighted achievements of this invention is the improvement of ecological parameters. By advancing how ammonia is combusted, the device minimizes harmful emissions, thereby reducing its environmental impact. Safety and reliability are also significantly enhanced, ensuring the device operates efficiently under various conditions.

The cooling chamber, especially at the chamber’s outlet, is equipped with a catalytic unit. This includes a flame sensor, a secondary air supply device, and a flame stabilizer, which collectively ensure that combustion is completed safely and effectively, even under varying operating scenarios.

Technical Advantages

Beyond its primary function, the device also excels technically by maximizing burner reliability and safety. Its design reflects a robust integration of elements catering to both primary and auxiliary functions. The result is not just energy efficiency but also a sustainable approach to utilizing ammonia, a crucial industrial chemical, as a fuel.