Electrolysis systems have gained significant attention in recent years due to their potential for generating clean energy. These systems use electricity to split water molecules into hydrogen and oxygen.

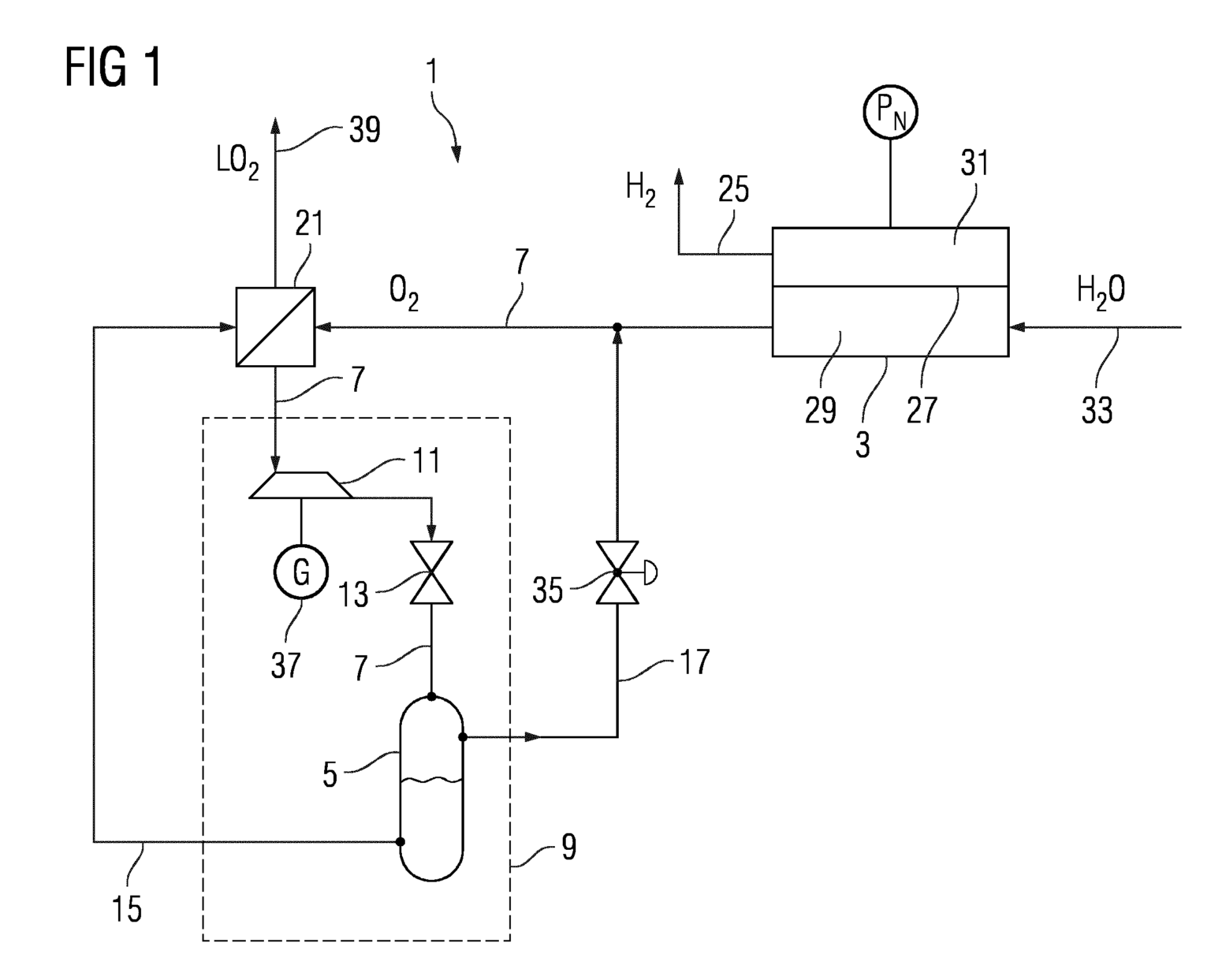

The latest development in this field involves an innovative electrolysis system designed by Siemens Energy Global GmbH & Co. KG. This system comes with a pressure electrolyser that can produce hydrogen and oxygen at high nominal pressures.

One of the standout features of this new electrolysis system is its ability to generate hydrogen (H2) and oxygen (O2) at high nominal pressures. This is particularly important for applications that require these gases at specific pressures for efficient operation.

The system includes an oxygen product gas line that leads from the pressure electrolyser to an expansion device. This ensures that the oxygen generated is managed effectively, minimizing waste and enhancing the overall efficiency of the system.

An essential component of this innovative setup is the expansion device connected to the oxygen product gas line. The primary purpose of this device is to regulate the pressure and temperature of the oxygen gas, which is produced at high nominal pressure. By expanding the pressurized oxygen, the system can cool it down, making it easier to handle and store.

Perhaps one of the most fascinating aspects of this system is its method for cooling and at least partially liquefying the oxygen product gas. After expansion, the pressurized oxygen is cooled, leading to its partial liquefaction. This results in the production of liquid oxygen (LO2), which has various industrial applications, including in medical settings and manufacturing processes that require extremely cold temperatures.

The method for operating this advanced electrolysis system is meticulously detailed. By employing pressure electrolysis, the system generates pressurized oxygen gas at a high nominal pressure. This gas is then expanded and subsequently cooled, partially turning it into liquid oxygen. This method not only maximizes efficiency but also ensures the safe and effective production and storage of both gaseous and liquid oxygen.

While it is crucial not to overstate the significance of this invention, it’s clear that this electrolysis system has the potential to contribute positively to several fields. From cleaner energy production to more efficient industrial processes, the applications are extensive. Its ability to generate both hydrogen and oxygen at high pressures makes it versatile and valuable for various industries.