The rapid development of offshore wind power in recent years presents a unique opportunity to address this freshwater challenge.

With large deck areas and variable loads, offshore floating wind turbines are well-suited to accommodate high-power hydrogen production equipment. Moreover, the abundant seawater surrounding these turbines offers a virtually limitless resource for hydrogen generation. However, direct seawater electrolysis remains in the developmental stage, leaving indirect seawater electrolysis, which couples seawater desalination with alkaline water electrolysis as the most viable solution.

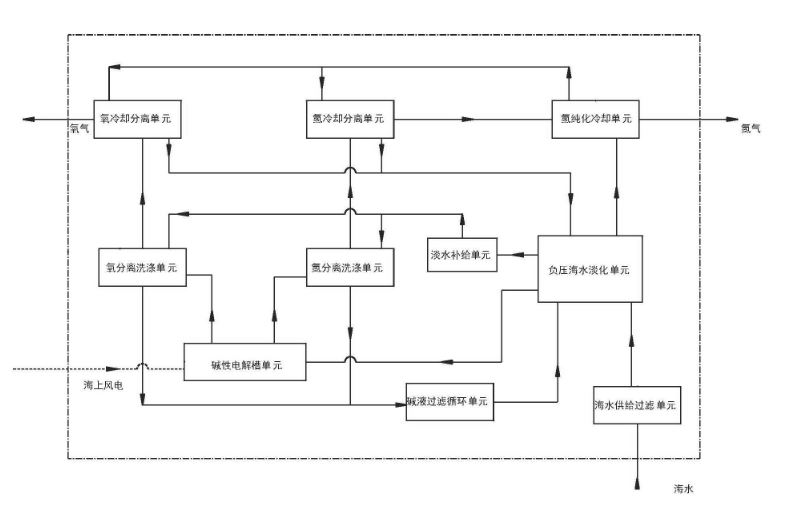

A Novel System for Indirect Seawater Electrolysis

A groundbreaking system and method have been developed to enable hydrogen production through water electrolysis suitable for offshore floating wind turbines. This innovative approach utilizes closed-loop freshwater as the cooling medium within the alkaline water electrolysis process. The heated freshwater is then employed as the heat source for seawater desalination in a negative pressure unit, establishing a closed freshwater cycle. This ingenious design enables efficient waste heat utilization from alkaline water electrolysis and facilitates indirect hydrogen production from seawater, addressing the freshwater scarcity issue.

Advantages of the System

The proposed system offers several significant advantages. It leverages wind power from offshore floating wind turbines and readily available seawater to generate hydrogen on-site. Employing a closed freshwater cycle for cooling and seawater desalination minimizes energy consumption and enhances the overall efficiency of the hydrogen production process. Furthermore, the system achieves self-sufficiency in freshwater by utilizing waste heat for low-temperature seawater desalination, ensuring a continuous supply of freshwater for electrolysis.

Technical Specifications

The system comprises several key components: an alkaline electrolyzer unit, oxygen and hydrogen separation cooling units, an alkaline solution filtering and circulating unit, an alkaline solution cooling unit, a negative pressure seawater desalination unit, and a circulating fresh water barge unit. The alkaline electrolyzer, powered by the wind turbine, decomposes freshwater into hydrogen and oxygen. The separation cooling units isolate and cool the generated gases, while the alkaline solution unit filters and recirculates the alkaline solution for reuse. The negative pressure seawater desalination unit converts seawater into freshwater, which is then stored and supplied for electrolysis. The circulating freshwater barge unit maintains the closed freshwater loop.

Implementation and Future Prospects

Implementing this system on offshore floating wind turbines could revolutionize green hydrogen production. Forming a self-contained wind-electricity-hydrogen-desalination system can accelerate the advancement of offshore green hydrogen technology, paving the way for a sustainable and decentralized energy future.