The patent for a Hydrogen Liquefaction System using an ammonia pre-cooling method presents an intriguing development in the domain of hydrogen storage.

This patent involves a sophisticated system that integrates a specific approach to cooling, aiming to optimize the liquefaction process of hydrogen—ensuring efficiency and potentially reducing costs.

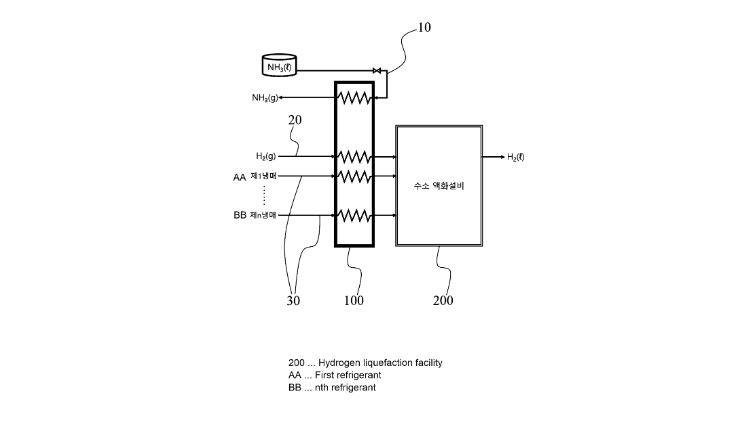

At its foundation, the system comprises multiple interconnected lines catering to different roles within the liquefaction facility. Central to this is the hydrogen liquefaction facility, which is responsible for liquefying hydrogen. Alongside, there is an ammonia supply line that provides ammonia (NH3) in a liquid state directly from an ammonia supply source. This particular inclusion of ammonia is critical as it is not just a traditional refrigerant but serves a unique role in pre-cooling.

Role of Ammonia in Pre-Cooling

The idea of pre-cooling hydrogen before its final liquefaction stage is a notable aspect of this innovation. By utilizing liquid ammonia, the system effectively lowers the temperature of hydrogen as well as any additional refrigerant passing through the facility. This is facilitated through a heat exchange unit where all the supply lines—ammonia, hydrogen, and refrigerant—converge. The cold properties of ammonia act to cool down the hydrogen and refrigerant significantly, enhancing the efficiency of the hydrogen liquefaction process.

The system holds potential for extensive use in industries requiring hydrogen as a key input, where cost-efficiency and energy optimization are essential.