A joint venture between Schaeffler and Symbio—has inaugurated a state-of-the-art production facility for fuel cell bipolar plates (BPP) in Haguenau, France. This venture is poised to become a cornerstone in the continent’s transition to sustainable transport, leveraging the strengths of its founding companies to mass-produce a critical component of fuel cell technology.

Strategic Importance of Bipolar Plates

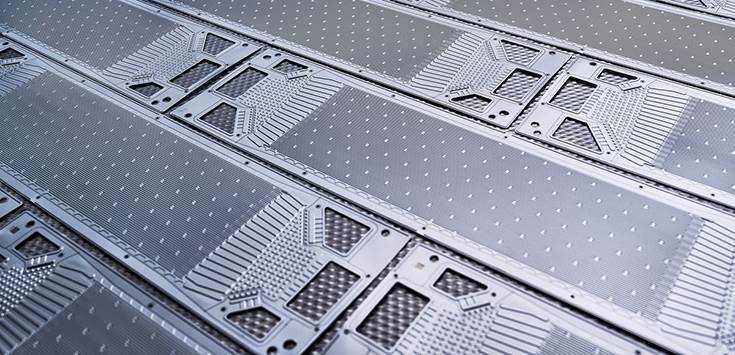

Bipolar plates are essential for fuel cell technology, acting as the core component facilitating the efficient flow of gases and electrons. They significantly influence fuel cells’ performance, durability, and efficiency, making their mass production crucial for the widespread adoption of hydrogen-powered vehicles.

Industrial Collaboration

The collaboration between Schaeffler and Symbio at Innoplate combines Schaeffler’s expertise in industrial excellence, steel processing, and coating technology with Symbio’s deep knowledge in fuel cell design and production. This synergy aims to accelerate the production of next-generation metallic BPP for the entire proton exchange membrane (PEM) fuel cell market, enhancing customer performance, capacity, and cost competitiveness.

Klaus Rosenfeld, CEO of Schaeffler AG, emphasized the pivotal role of hydrogen in future mobility. “At Schaeffler, we are convinced that hydrogen will play a fundamental role in tomorrow’s sustainable mobility, especially in heavy-duty areas. By starting the production of the next-generation bipolar plate for fuel cells in our joint venture Innoplate with Symbio, we are proud that our innovative production technologies and industrial know-how can contribute to cleaner and climate-friendly mobility and strengthen the Franco-German partnership.”

Production Capacity and Future Goals

The new facility in Haguenau began operations in the first quarter of this year, initially producing 4 million bipolar plates annually. However, Innoplate has ambitious plans to ramp up production to 50 million units annually by 2030. This substantial increase in capacity is expected to significantly support the ramp-up of hydrogen mobility across Europe, addressing both the current and future demands of the market.

Philippe Rosier, CEO of Symbio, highlighted the importance of this venture for strategic sourcing and performance enhancement. “Fuel cell bipolar plates are a critical component of fuel cell systems. Innoplate’s serial production capability is instrumental in securing our strategic sourcing and enabling enhanced system performance and an effective cost competitiveness step up. Symbio is honored to join forces with Schaeffler to reinforce the European supply chain for hydrogen fuel cells with an innovative production system and cutting-edge technology.”