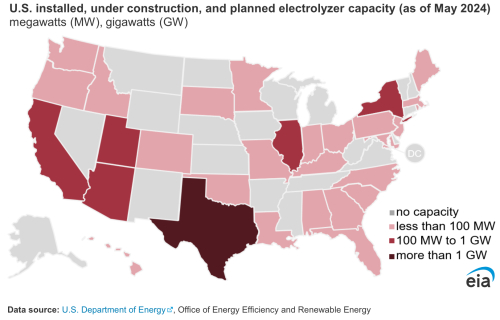

According to the US Department of Energy’s Hydrogen Program Record, these installations could increase the country’s electrolyzer capacity from 116 megawatts (MW) to 4,524 MW. If all planned projects come to fruition, annual hydrogen production through electrolysis could reach approximately 0.72 million metric tons (MMmt), compared to the current 10 MMmt produced from fossil fuels and as a byproduct from other industrial sources.

The Hydrogen Production Landscape

Hydrogen production in the US is predominantly achieved through steam methane reforming (SMR), which separates hydrogen from hydrocarbons like natural gas and coal. This method, however, generates significant carbon dioxide and carbon monoxide emissions, necessitating carbon capture and sequestration to mitigate its environmental impact. According to the US Energy Information Administration (EIA), the US has an SMR capacity of 7.6 MMmt of hydrogen per year.

In contrast, hydrogen produced via electrolysis is a cleaner alternative. Electrolysis uses an electrical current to split water into hydrogen and oxygen, with oxygen being the only byproduct. When powered by renewable energy sources, electrolysis can produce carbon-neutral hydrogen, positioning it as a key technology in the transition to sustainable energy.

Advancements in Electrolyzer Technology

Electrolyzers are crucial for producing green hydrogen, and two primary technologies are commercially available: Proton Exchange Membrane (PEM) and Alkaline electrolyzers. Each has distinct characteristics in terms of cost, start-up times, and materials used:

Proton Exchange Membrane (PEM): PEM electrolyzers are known for their compact size and ability to operate at high current densities. They offer rapid start-up times and can respond quickly to fluctuations in electricity supply, making them well-suited for integration with intermittent renewable energy sources such as wind and solar power.

Alkaline Electrolyzers: These are more mature and typically have lower capital costs than PEM electrolyzers. They are also robust and durable, making them suitable for large-scale, continuous hydrogen production.

Both technologies require further development to enhance efficiency and reduce costs, ensuring they remain competitive in the evolving energy market.

Incentives and Policy Support

The expansion of electrolyzer capacity in the US is supported by favorable policy measures. Electrolyzers that meet specific low carbon intensity thresholds may qualify for production tax credits if construction begins by 2033. This incentive is designed to accelerate the deployment of green hydrogen technologies and reduce reliance on fossil fuel-based hydrogen production.

Potential Impact and Future Outlook

The planned expansion of electrolyzer capacity represents a significant shift towards cleaner hydrogen production in the US. By increasing the share of hydrogen produced via electrolysis, the US can reduce its carbon footprint and support the broader decarbonization and energy transition goals.

Environmental Benefits: Electrolyzers powered by renewable energy produce green hydrogen without the carbon emissions associated with SMR. This transition can substantially lower greenhouse gas emissions from hydrogen production, contributing to climate goals and improving air quality.

Economic Growth: The hydrogen industry has the potential to create new jobs and stimulate economic growth. The development of electrolyzer manufacturing, installation, and maintenance industries can drive investment and innovation in the clean energy sector.

Energy Security: Expanding domestic hydrogen production capabilities can enhance energy security by reducing dependence on imported fossil fuels. Hydrogen can also be a versatile energy carrier, supporting grid stability and integrating with various renewable energy sources.