The latest patent, filed by the Paul Scherrer Institute, introduces a novel approach to plant design that offers remarkable flexibility.

This patent outlines a method and system for producing hydrogen and/or methanol, leveraging multipurpose reactors to minimize capital costs while integrating hydrogen fuel and biomass.

One of the standout features of this patented invention is its adaptability concerning feedstock and the resulting product spectrum. This system allows the use of carbonaceous feedstock from sources like biomass and waste, promoting environmental sustainability. It supports the integration of CO2 as a feedstock, alongside hydrogen, for the production of storable energy carriers such as hydrocarbons. This level of flexibility ensures that the plant can pivot its output based on the availability of renewable resources or specific market demands.

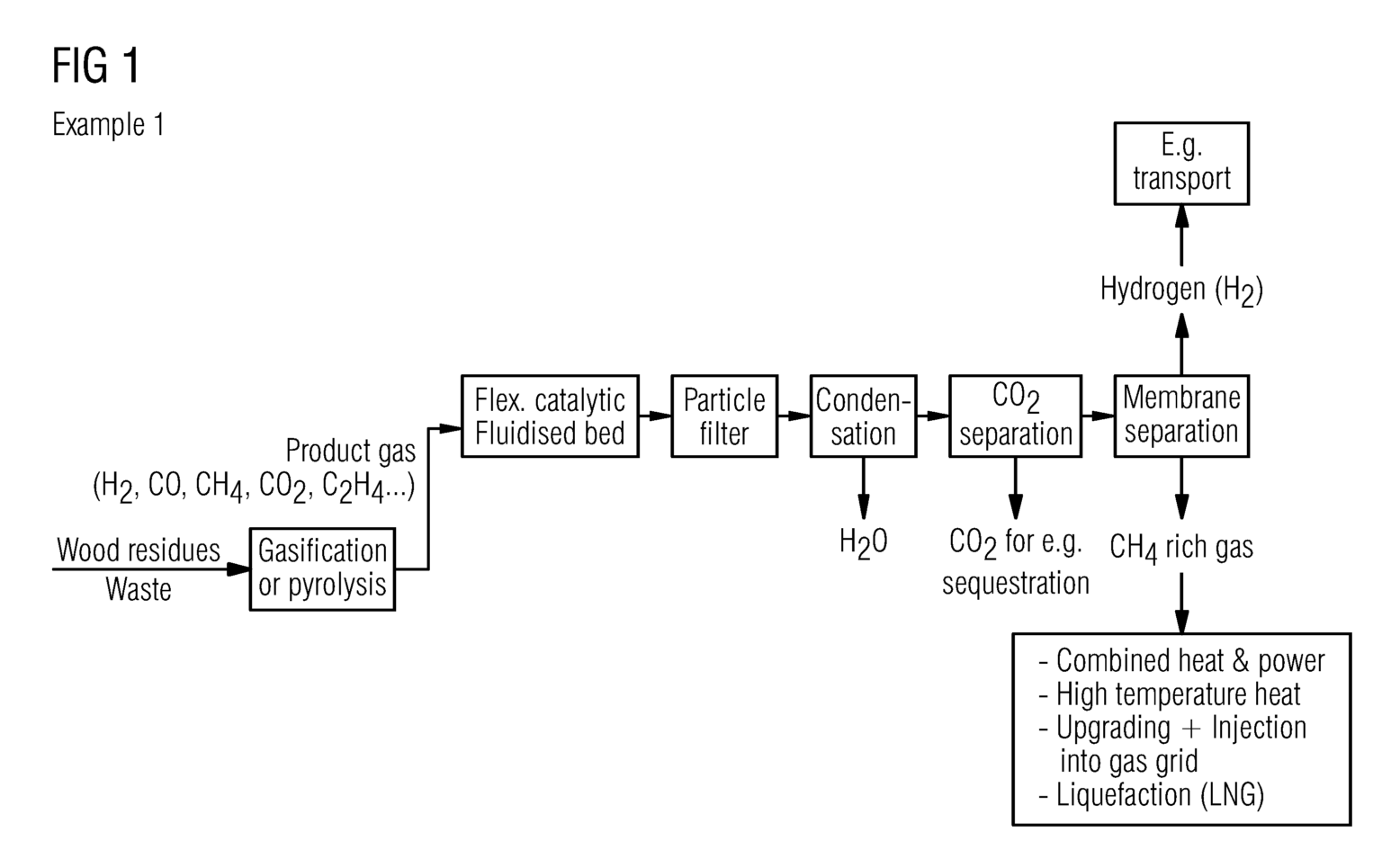

At the core of this method is a thermochemical process involving gasification or pyrolysis. This process converts the carbonaceous feedstock into a product gas containing essential components like CO and H2, as well as optional unsaturated hydrocarbons such as ethylene, acetylene, and benzene. This conversion is a vital initial step in creating the flexibility and efficiency that the patented system promises.

A critical component of the system described in the patent is the fluidized bed reactor. This reactor enables the reaction of the product gas with a catalyst or sorbent composed of materials like copper, molybdenum, and iron. These materials are chosen for their ability to support the conversion of CO and H2O into either hydrogen and CO2 or methanol, based on operational conditions. The manipulation of conditions such as pressure, temperature, and heat exchange provides control over the plant’s output, demonstrating the system’s adaptability and potential for optimized energy production.

Upgrading and Separation Process

Following the reaction in the fluidized bed reactor, the product gas is guided through an upgrading section designed to further refine the output. This section includes a particle filter and potentially a condensation step, along with various separation units. These might encompass technologies like membranes, scrubbers, pressure swing adsorption, temperature swing adsorption, chemisorption, or liquefaction. The ultimate goal of this process is to separate a hydrogen-rich or methanol-rich stream, depending on the desired outcome.