The quest for sustainable energy sources is continually evolving, and one innovative solution comes from H2-SPHERE GMBH. They have developed a method for producing green hydrogen through an energetically self-sustained process. This method utilizes pyrite, which can be extracted from mine waste, thus offering dual benefits of waste management and clean energy production.

Separation and Enrichment of Mine Waste Material

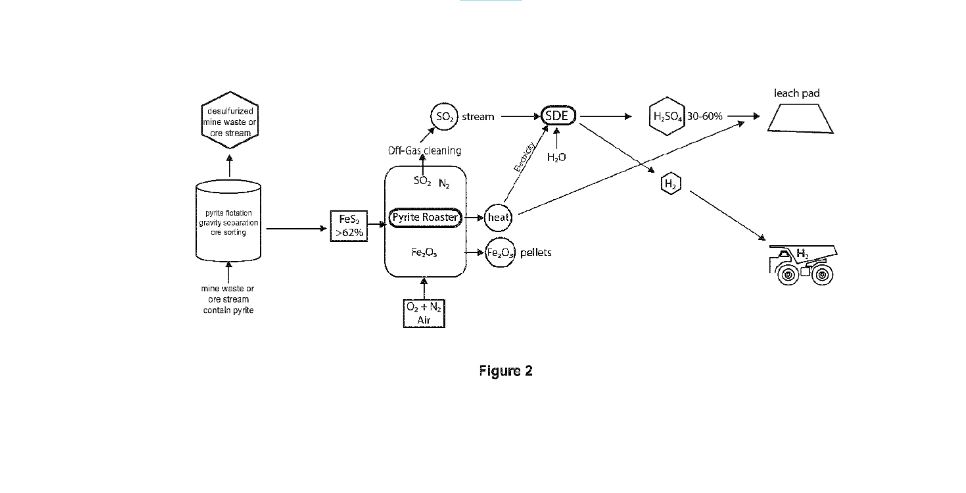

To kickstart the process, mine waste material rich in pyrite is separated and enriched to obtain a concentrated form. Mine waste is mainly disposed of tailings or active tailings streams, and it contains significant amounts of pyrite that can be repurposed rather than discarded.

Oxidation of Pyrite Concentrate

The next step involves oxidizing the pyrite concentrate to produce SO2 gas. This forms the basis for further chemical reactions crucial to the entire method. The oxidation process is designed to be efficient, ensuring maximum extraction of SO2 gas.

Separation of SO2 Gas

Once SO2 gas is generated, it is separated from the other oxidation by-products. The separation process ensures that only pure SO2 gas is processed further, minimizing impurities and enhancing the efficiency of the following steps.

Utilization of SO2 Gas

The separated SO2 gas is then utilized to generate hydrogen gas (H2) and sulfuric acid (H2SO4) via two possible processes: the SO2-depolarized electrolyzer (SDE) process or the sulfur-iodine-cycle (S-I-cycle) process. Both these processes offer unique pathways to convert SO2 into useful end products.

The SO2-Depolarized Electrolyzer Process

In the SO2-depolarized electrolyzer process, SO2 acts as a depolarizing agent, which assists in the electrolysis of water to produce hydrogen gas. This method is particularly attractive because it can be integrated into electrolysis systems, making it a feasible option for various applications.

The Sulfur-Iodine-Cycle Process

Alternatively, the sulfur-iodine cycle process can also be utilized. This chemical cycle involves multiple steps, in which iodine and sulfur dioxide are used to produce hydrogen gas. Though more complex, this process is highly efficient and can be scaled up for industrial applications.

H2-SPHERE GMBH’s innovative method of producing green hydrogen from pyrite in mine waste creates a valuable energy source and addresses environmental concerns associated with mine waste. By focusing on both the SO2-depolarized electrolyzer and sulfur-iodine-cycle processes, the method provides versatile approaches to hydrogen production. This patent signifies a substantial advancement in sustainable energy, potentially setting the stage for broader adoption of green hydrogen across various industries.