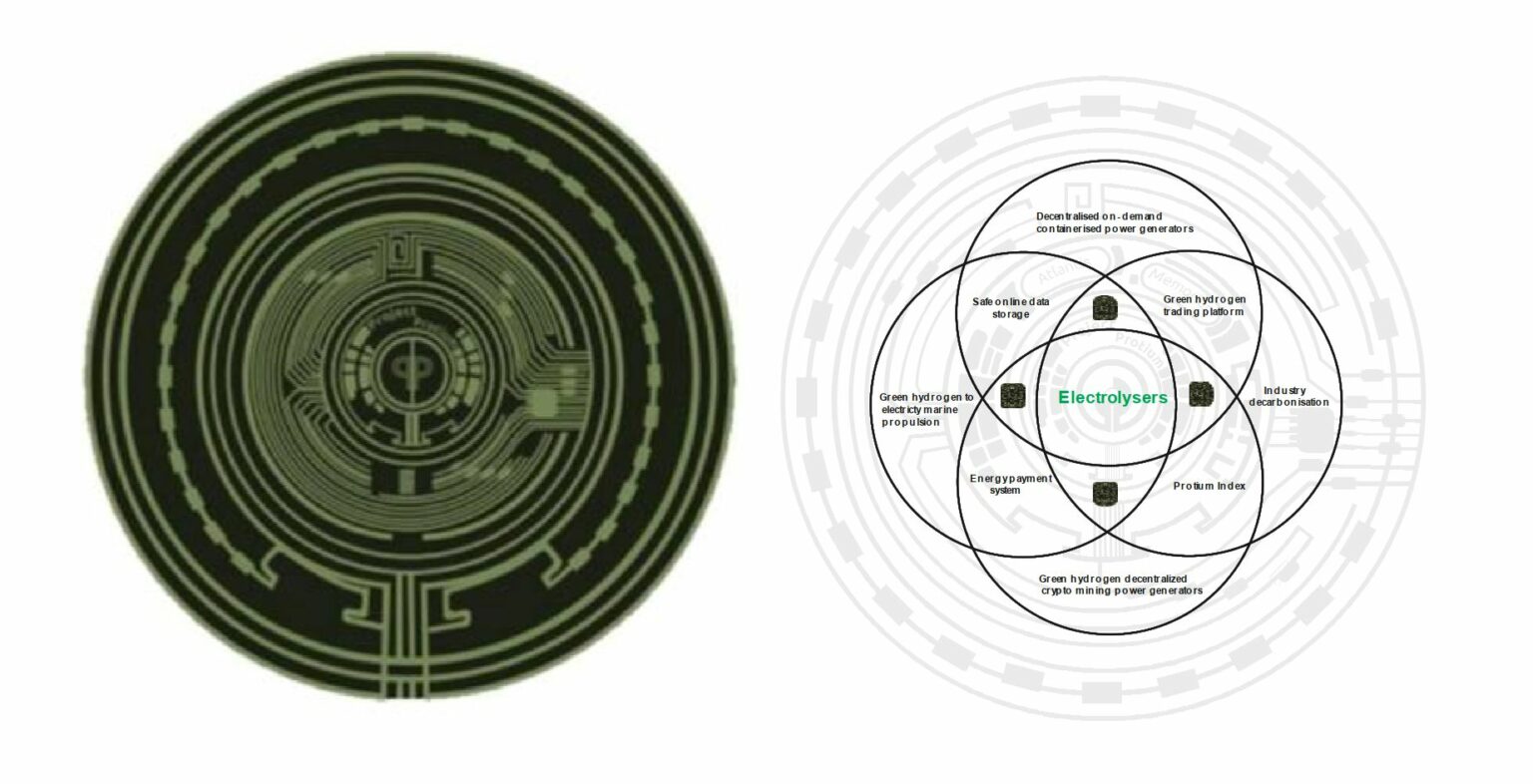

In the global quest for sustainable energy solutions, green hydrogen has emerged as a pivotal technology for achieving net-zero emissions. This paper outlines a revolutionary, award-winning decentralized green hydrogen production system.

Utilizing advancements in magnetics, acoustics, catalyst design, nanotechnology, and pulsed power management, this system demonstrates unparalleled efficiency in producing hydrogen from seawater. With its ability to reduce the power required for electrolysis while significantly increasing gas production, this solution has the potential to replace traditional electrolysis methods, offering a cost-effective, scalable, and environmentally friendly source of green fuel.

The energy landscape is rapidly shifting toward renewable energy sources. However, one of the critical challenges is creating a reliable, sustainable energy storage system. Green hydrogen is widely considered the fuel of the future, offering clean energy that can be produced from renewable sources. Despite its promise, current methods of hydrogen production are inefficient, costly, and reliant on limited fresh water supplies. This paper introduces a revolutionary system that leverages cutting-edge technologies to overcome these challenges and make green hydrogen production from seawater both feasible and economically viable.

Current Limitations of Traditional Electrolysis

Conventional electrolysis for hydrogen production is an energy-intensive process, requiring significant electrical input, often sourced from non-renewable means, and relies heavily on pure water resources. These systems typically operate with efficiencies of 60-70%, with overall well-to-wheel efficiency as low as 20-30% when accounting for the production and transportation of hydrogen. Furthermore, the high costs of rare catalysts and system inefficiencies have hindered the widespread adoption of green hydrogen technologies.

A Breakthrough in Green Hydrogen Production

Our decentralized, fully on-demand green hydrogen system represents a paradigm shift in electrolysis technology. Key innovations include:

- Magnetics Enhancements: Our system employs advanced magnetic fields, reducing the power needed for electrolysis by over 17% while tripling the amount of hydrogen gas produced. The magnetic fields optimize the ion flow and charge separation, significantly increasing gas output efficiency.

- Acoustic Integration: Acoustics technology reduces the power needed for electrolysis by an additional 25%. By applying ultrasonic frequencies, we enhance cavitation effects, decreasing resistance at the electrolyte-electrode interface, resulting in a dramatic reduction in energy consumption.

- Superior Catalyst Design: Unlike traditional systems that rely on expensive and rare catalysts such as platinum our solution uses earth-abundant materials to create a highly effective catalyst that make up our electrodes. This superior catalyst accelerates the electrochemical reactions within the electrolyzer, reducing overall reaction times and further minimizing energy input.

- Magnetic Nanocoating: A novel magnetic nanocoating is applied to the electrodes, which aids in optimizing the overall magnetic influence on the electrolysis process. This nanocoating enhances the magnetic field’s impact on ion mobility while also acting as a protective layer to suppress corrosion, further contributing to efficiency gains.

- Power Management System: Our system incorporates an advanced power management and distribution system that can further reduce energy consumption by an additional 10% by optimizing energy delivery to the electrolyzer, preventing energy wastage and improving overall efficiency.

Comparative Efficiency

With a total reduction of over 50% in power consumption and factoring in the tripling of hydrogen production, the result is a revolutionary leap in both cost-efficiency and energy output. This significant improvement makes it viable to produce hydrogen on a decentralized, on-demand basis, providing localized energy solutions without the need for vast infrastructure and transportation networks.

Seawater as a Resource

Our system can use seawater as the feedstock for electrolysis eliminating the need for highly purified fresh water resources. By leveraging an ultrasonic acoustic system and UV we can effectively manage the seawater’s impurities while simultaneously ensuring the highest purity levels of hydrogen output. This makes the system not only sustainable but also highly scalable, especially in regions with limited access to freshwater.

Economic Viability and Scalability

Traditional hydrogen production methods are costly due to high energy demands and the use of rare catalysts. Our system, with its reliance on earth-abundant materials and significant energy efficiency improvements, drastically reduces the cost per kilogram of hydrogen produced. Furthermore, its decentralized nature allows for scalability—from small local installations to large-scale industrial setups—eliminating the need for massive hydrogen transport infrastructure and making green hydrogen production more accessible globally.

Environmental Impact

The environmental benefits of this system are multifaceted. Not only does it avoid the need for renewable or non-renewable energy sources to power electrolysis, but it also addresses the global water scarcity issue by utilizing seawater. Furthermore, the system’s increased efficiency reduces the carbon footprint associated with hydrogen production, storage, and distribution while producing approximately 270 litres of pure water for every megawatts of electricity produced.

This revolutionary green hydrogen production system offers a superior alternative to traditional electrolysis solutions. By reducing energy consumption by over 50%, tripling hydrogen output, and leveraging cost-effective, earth-abundant catalysts, this system sets a new benchmark for the hydrogen economy. Its ability to produce green hydrogen from seawater makes it a key technology for turning the world into a green energy haven. As nations strive to meet their renewable energy targets, our decentralized and fully on-demand system stands ready to play a crucial role in the global transition to sustainable energy.