An interesting innovation in the field of hydrogen production is highlighted by the patent titled “Ammonia Cracker Reactor Module.”

This application was filed by CatalSys Limited on January 2, 2025. The team behind this inventive endeavor includes a roster of talented inventors focused on advancing energy technology.

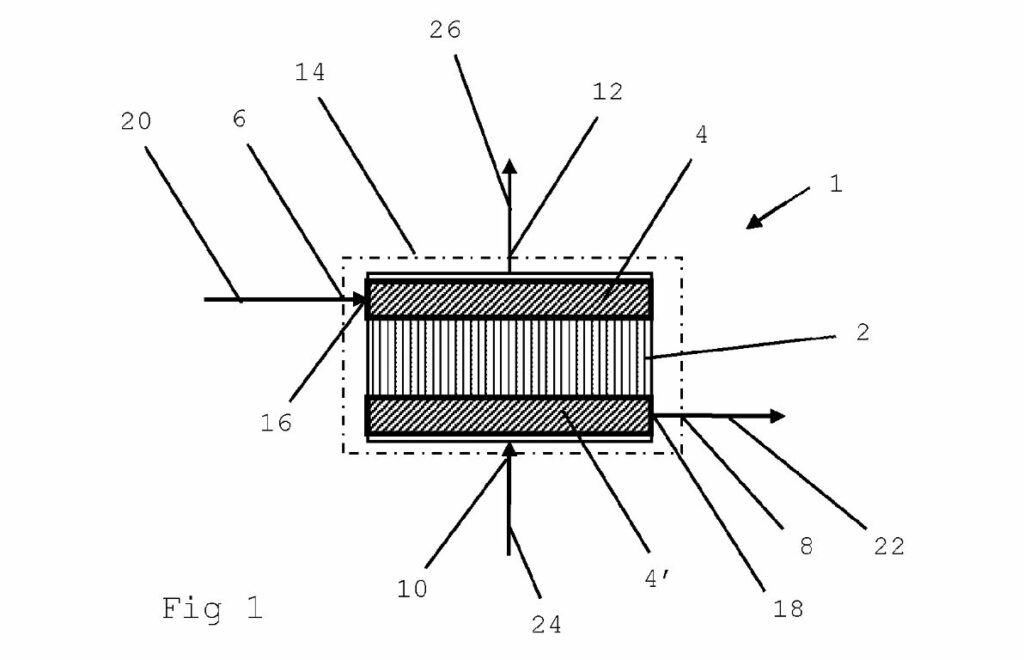

At the core of this patent is the concept of an ammonia cracker reactor module. This module integrates crucial components: a heat exchanger and a catalyst cartridge. These components work in tandem to transform ammonia into hydrogen, an essential process in the quest for cleaner energy solutions.

The ammonia cracker reactor module is designed with several key inlets and outlets for both process fluids and working fluids. Here’s how it operates:

1. Process Fluid Pathway: When process fluid enters through the module inlet, it passes through a combined system of the catalyst cartridge and heat exchanger. This configuration ensures the efficient conversion of ammonia in the process fluid into hydrogen before reaching the module outlet.

2. Catalyst Cartridge Role: Central to the conversion process is the catalyst material contained within the cartridge. It is designed to come into contact with the process fluid, catalyzing the crucial reaction that yields hydrogen from ammonia.

3. Working Fluid Pathway: Simultaneously, a working fluid enters through its designated inlet, travels through the heat exchanger, and exits via the outlet. The primary role of the heat exchanger is to facilitate heat transfer between the process and working fluids.

One of the notable design features of this reactor module is the detachable catalyst cartridge. It can be removed from the heat exchanger interfaces, either at the inlet or outlet. This modulatory design offers flexibility and ease of maintenance, enabling replacement or inspection of the catalyst cartridge without affecting the rest of the system.

This patent also extends its novelty to standalone catalyst cartridges and fuel systems that utilize the described reactor module, thus expanding its potential applications in various hydrogen production settings.

Stay updated on the latest in energy! Follow us on LinkedIn, Facebook, and X for real-time news and insights. Don’t miss out on exclusive interviews and webinars—subscribe to our YouTube channel today! Join our community and be part of the conversation shaping the future of energy.