A new patent titled “Method of Hydrogen Production from Biomass-Based Synthesis Gas” has been filed by inventors with the support of MASH MAKES A/S. This invention details a method utilizing a biomass-based hydrogen production system, including a pyrolysis reactor and a gasification reactor.

Unique Features and Improvements

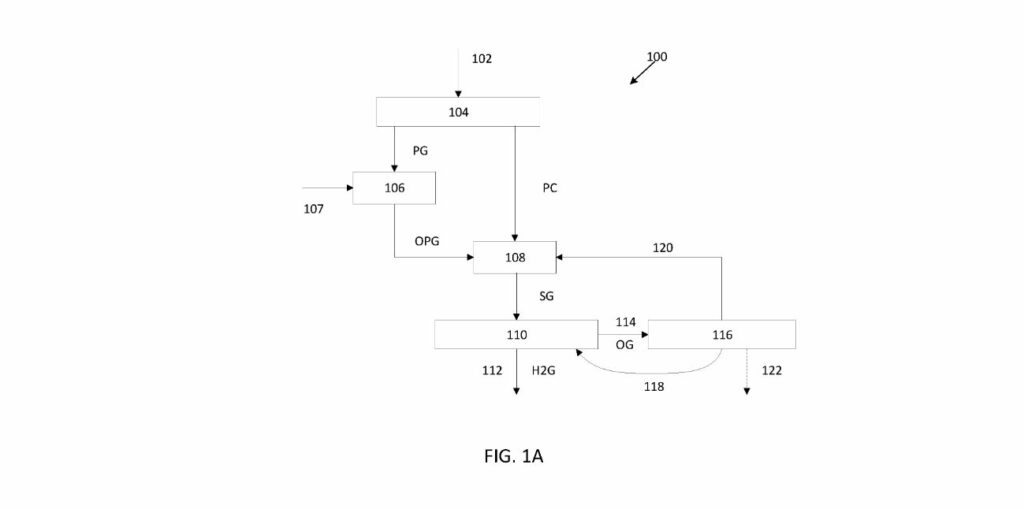

The primary innovation detailed in this patent lies in its comprehensive approach to hydrogen production. The method begins with pyrolysing a biomass feedstock in a pyrolysis reactor to generate pyrolysis gas (PG) and solid pyrolysis char (PC). Subsequent steps involve partially oxidizing the pyrolysis gas and gasifying the pyrolysis char using the oxidized pyrolysis gas, ultimately producing a synthesis gas (SG) rich in hydrogen molecules. This synthesis gas is then separated into a hydrogen-rich stream (H2G) and an off-gas (OG) stream, with the latter containing lower concentrations of hydrogen and other synthesis gas elements.

A notable feature is integrating an energy conversion system (ECS) to extract mechanical, electrical, and thermal energy from the off-gas. This energy is then reutilized to power the biomass-based hydrogen production system, enhancing energy efficiency and sustainability.

Potential Applications

This technology has myriad potential applications, particularly in renewable energy and waste management. It provides an efficient method to convert biomass—an abundant renewable resource—into hydrogen, which can be used as a clean fuel for various applications, including transportation, power generation, and industrial processes.

Competitive Analysis

Compared to existing hydrogen production methods, such as steam methane reforming (SMR) and water electrolysis, this biomass-based approach offers several advantages. SMR, while currently the most common method, relies heavily on natural gas, a fossil fuel, and produces significant carbon emissions. Water electrolysis, though cleaner, often requires considerable amounts of electrical energy typically sourced from non-renewable grids.

In contrast, the patented biomass-based hydrogen production offers a renewable and potentially carbon-neutral alternative. Utilizing both the pyrolysis and gasification processes and energy recovery from off-gases, this method likely presents a lower overall environmental footprint and could lead to energy cost savings.

Technical Specifications and Processes

Key technical elements of the patent include:

– Pyrolysis Reactor: Converts biomass feedstock into pyrolysis gas (PG) and solid pyrolysis char (PC).

– Oxidation: Partial oxidation of the pyrolysis gas using an oxidizing gas.

– Gasification Reactor: Uses oxidized pyrolysis gas to gasify pyrolysis char, yielding a hydrogen-rich synthesis gas (SG).

– Energy Conversion System (ECS): Extracts mechanical, electrical, and thermal energy from the off-gas for reuse within the system.

Key Takeaways

The method outlined in this patent introduces a sustainable, efficient, and renewable approach to hydrogen production. By effectively integrating biomass feedstocks, the dual reactor system, and energy recovery mechanisms, this technology provides a compelling alternative to conventional hydrogen production methods. Its potential to reduce costs and environmental impacts positions it as a significant contender in the evolving hydrogen market.