In the realm of hydrogen production technology, advancements are continually being pursued to enhance efficiency and sustainability. One such advancement is encapsulated in a recent patent filed by the Nederlandse Organisatie Voor Toegepast-Natuurwetenschappelijk Onderzoek (TNO).

This patent outlines a novel design for a catalyst sheet specifically tailored for use in proton exchange membrane (PEM) and anion exchange membrane (AEM) water electrolyzers. Let’s dive into the components and advantages of this innovation.

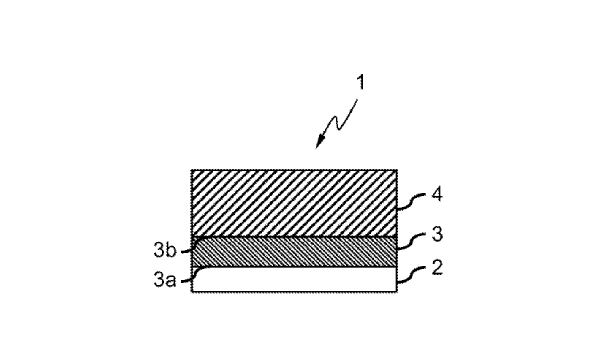

The core of this invention lies in its unique composition. The catalyst sheet comprises two primary elements: a substrate sheet and a deposited catalyst material. The substrate sheet is characterized by its porosity and electrical conductivity, which are fundamental properties for the function of electrolyzers. The porosity allows for efficient distribution and movement of reactants and products, while its conductivity is crucial for the transfer of electrical currents, driving the electrolytic process.

Applications in Electrolyzers

The primary application of this catalyst sheet is within PEM and AEM water electrolyzers. These types of electrolyzers are pivotal in hydrogen production as they facilitate the electrochemical splitting of water into hydrogen and oxygen. By integrating this advanced catalyst sheet, the efficiency of the electrolyzers can be significantly enhanced. This is due to improved electron flow and reactant accessibility provided by the sheet’s porous and conductive nature, translating into more efficient hydrogen production.

The disclosed catalyst sheet not only supports the process within electrolyzers but also proposes a method that could revolutionize hydrogen production. The design aims to lower operational costs and increase the output of hydrogen, a clean energy source, thus contributing to the transition toward more sustainable energy systems.