Institutul Național de Cercetare-Dezvoltare pentru Tehnologii Criogenice și Izotopice has patented high-pressure hydrogen-charging system.

Designed for the partial or total hydrogen-filling of automobile tank vessels, this system is particularly adept at handling very high pressures, making it a significant advancement in hydrogen vehicle technology.

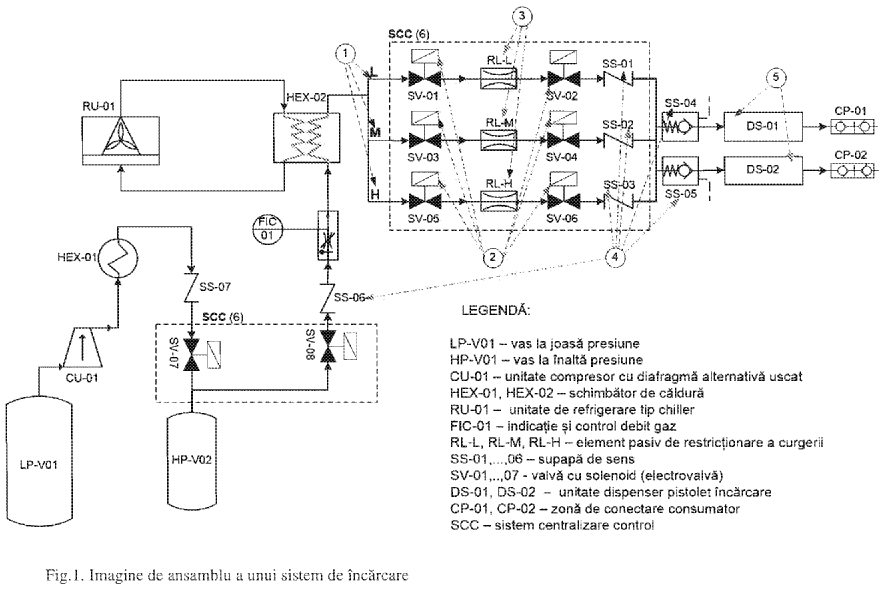

At the heart of the invention is a sophisticated network of three different connection lines referred to as H-M-L. These lines are designed to operate either sequentially or in parallel, depending on various constructive parameters and working conditions. The choice of line operation is influenced by factors such as the existing pressure within the vehicle’s tank or an additional vessel.

The inclusion of batteries of electrovalves (labeled SV-01 to SV-06) offers precise control over the hydrogen flow. These valves operate under the guidance of a Centralized Control System (SSC), which receives input from charging pistols (DS-01 and DS-02). This sophisticated control setup ensures that the hydrogen gas is delivered in a controlled manner, taking into account pressure and temperature limits to safeguard the vehicle’s tank.

Flow restriction elements, identified as RL-H, RL-M, and RL-L, play a crucial role in regulating the amount of hydrogen delivered to the tank. These elements passively control the flow, ensuring that the constructive parameters of the vehicle tank—such as pressure tolerance—are not exceeded. The direction and integrity of the gas flow are further secured by a series of direction valves (SS-01 to SS-06), which prevent backflow and ensure that the hydrogen is directed effectively into the tank.

One of the standout features of this system is its ability to manage high-pressure hydrogen refueling safely and efficiently. With its carefully designed internal structure, the system allows for gas lamination, reducing risks associated with rapid pressure increases. This focus on safety and efficiency could greatly enhance the adoption of hydrogen technology in automotive applications.

Stay updated on the latest in energy! Follow us on LinkedIn, Facebook, and X for real-time news and insights. Don’t miss out on exclusive interviews and webinars—subscribe to our YouTube channel today! Join our community and be part of the conversation shaping the future of energy.