DENSO CORPORATION recently filed a patent, for an advanced hydrogen production system. This cutting-edge technology is designed to enhance the efficiency and flexibility of hydrogen production through electrolysis, offering a new approach to managing energy use in this context.

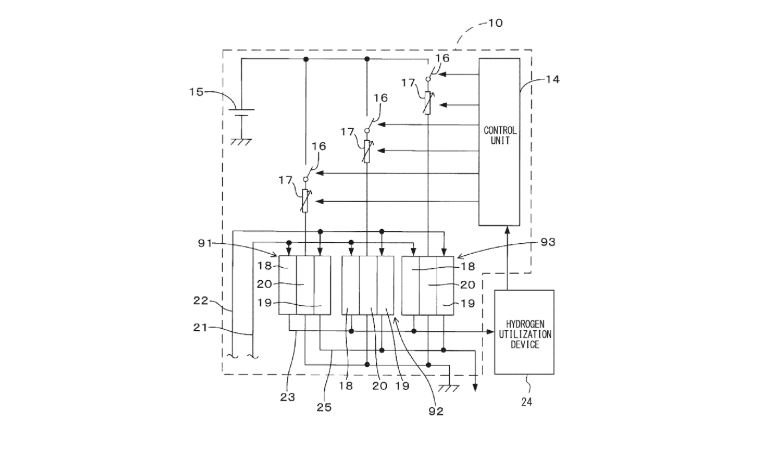

The patented system comprises two main components: cell stacks and a control unit. The cell stacks are responsible for the physical process of hydrogen production by electrolyzing water using the supplied power. This method of producing hydrogen is both environmentally friendly and sustainable, relying on the separation of water molecules into hydrogen and oxygen using electricity.

Central to the system’s novelty is its control unit, which provides nuanced control over individual cell stacks. The control unit can execute two distinct types of controls. The first is a load adjustment control, which tweaks the voltage or current supplied to specific cell stacks. This adjustment is made based on the overall hydrogen production needs of all cell stacks within the system. The second type of control is an ON/OFF control, allowing the control unit to switch the power supply to any specific cell stack on or off.

By implementing both load adjustment and ON/OFF controls, the system can optimize energy use according to current hydrogen production requirements. This flexibility ensures that energy is used efficiently, potentially lowering costs and enhancing the sustainability of hydrogen production processes. Additionally, the ability to target individual cell stacks means that the system can adapt to varying operational conditions and production demands.

Stay updated on the latest in energy! Follow us on LinkedIn, Facebook, and X for real-time news and insights. Don’t miss out on exclusive interviews and webinars—subscribe to our YouTube channel today! Join our community and be part of the conversation shaping the future of energy.