Kraken Technology Holdings recently filed a noteworthy patent, “A method for providing energy to commercial or industrial operations,” on June 25, 2024. The team of inventors behind this significant contribution is currently unspecified but is represented by the assignee, Kraken Technology Holdings, LLC. This patented technology introduces a novel approach to harnessing waste heat generated during hydrogen production for various commercial and industrial applications, such as greenhouses and algae farms.

Features and Improvements

The proposed method stands out due to several unique features and improvements over existing solutions:

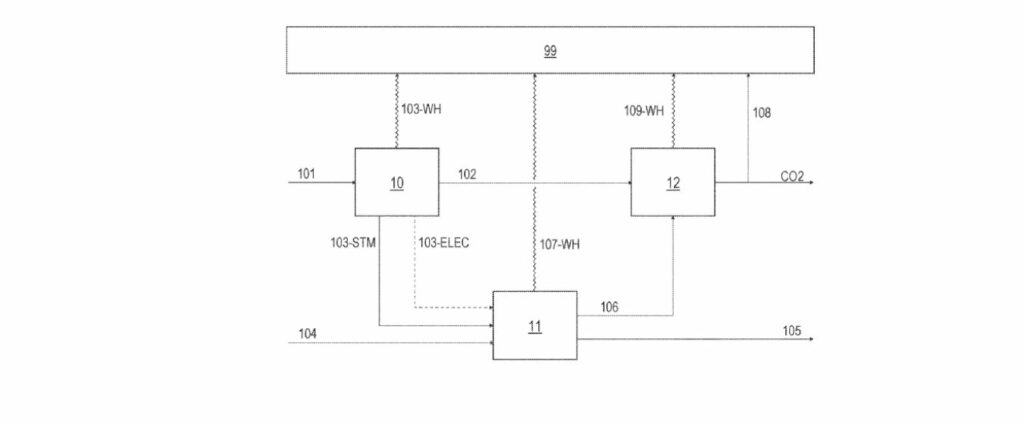

1. Low Carbon Intensity: The hydrogen produced through this method boasts an impressively low carbon intensity, with the patent specifying values preferably below 1.0 kg CO₂e/kg H₂, more preferably below 0.45 kg CO₂e/kg H₂, and most preferably striving for 0.0 kg CO₂e/kg H₂. This is a significant leap towards more sustainable hydrogen production practices.

2. Utilization of Biomass Power Plants: The method uses biomass power plants to supply the energy required for hydrogen production. This supports renewable energy integration and ensures a circular and sustainable energy loop.

3. Carbon Capture: The process includes advanced carbon capture mechanisms to mitigate further CO₂ emissions from hydrogen production and the biomass power plant, thus achieving cleaner overall operations.

4. Waste Heat Recovery: A key innovation lies in efficiently recovering waste heat generated from hydrogen production and converting it into usable thermal energy. This captured thermal energy can be redirected to support various commercial and industrial operations, enhancing energy utilization efficiency.

Potential Applications

This patented technology has varied applications across several sectors, offering potential benefits including:

– Agricultural Greenhouses: Utilizing thermal energy to maintain optimal growing conditions and enhance crop yields.

– Algae Farms: Assisting in achieving the precise thermal environments required for cultivating algae, which can be used for biofuels, pharmaceuticals, and other purposes.

– Industrial Heating: Providing thermal energy solutions for diverse industrial processes, reducing dependence on traditional energy sources.

Market Impact

The impact of this patent on the hydrogen market could be profound:

– Environmental Benefits: By lowering the carbon intensity of hydrogen production and utilizing waste heat, this method significantly reduces greenhouse gas emissions, aligning with global sustainability goals.

– Cost Efficiency: The dual benefit of hydrogen production and waste heat utilization can lower operational costs, making hydrogen a more attractive energy source for various industries.

– Market Differentiation: Companies adopting this patented method may achieve competitive advantages through enhanced sustainability credentials and operational efficiency.

Competitive Analysis

In comparison to existing hydrogen production technologies, the patented method offers several distinctive advantages:

– Enhanced Sustainability: The focus on low-carbon intensity and carbon capture mechanisms represents a considerable improvement over conventional hydrogen production processes.

– Integrated Energy Solutions: Combining hydrogen production with waste heat recovery is a forward-looking approach, setting it apart from existing technologies that do not capitalize on waste heat’s potential.

– Renewable Orientation: Using biomass power plants to supply energy for hydrogen production is a pioneering step that emphasizes the shift towards integrating renewable energy into industrial processes.

Technical Specifications

The patent outlines the process of converting hydrocarbon feedstocks to hydrogen via a reforming process. Substantial amounts, preferably all, of the required energy are derived from biomass power plants. The focus on optimizing carbon intensity through capturing and processing carbon dioxide streams plays a pivotal role in ensuring minimal environmental impact.