The patent filed by the Nanjing Institute of Microinterface Technology introduces a micro-interface enhanced oxidation system designed to improve the preparation process of hydrogen peroxide.

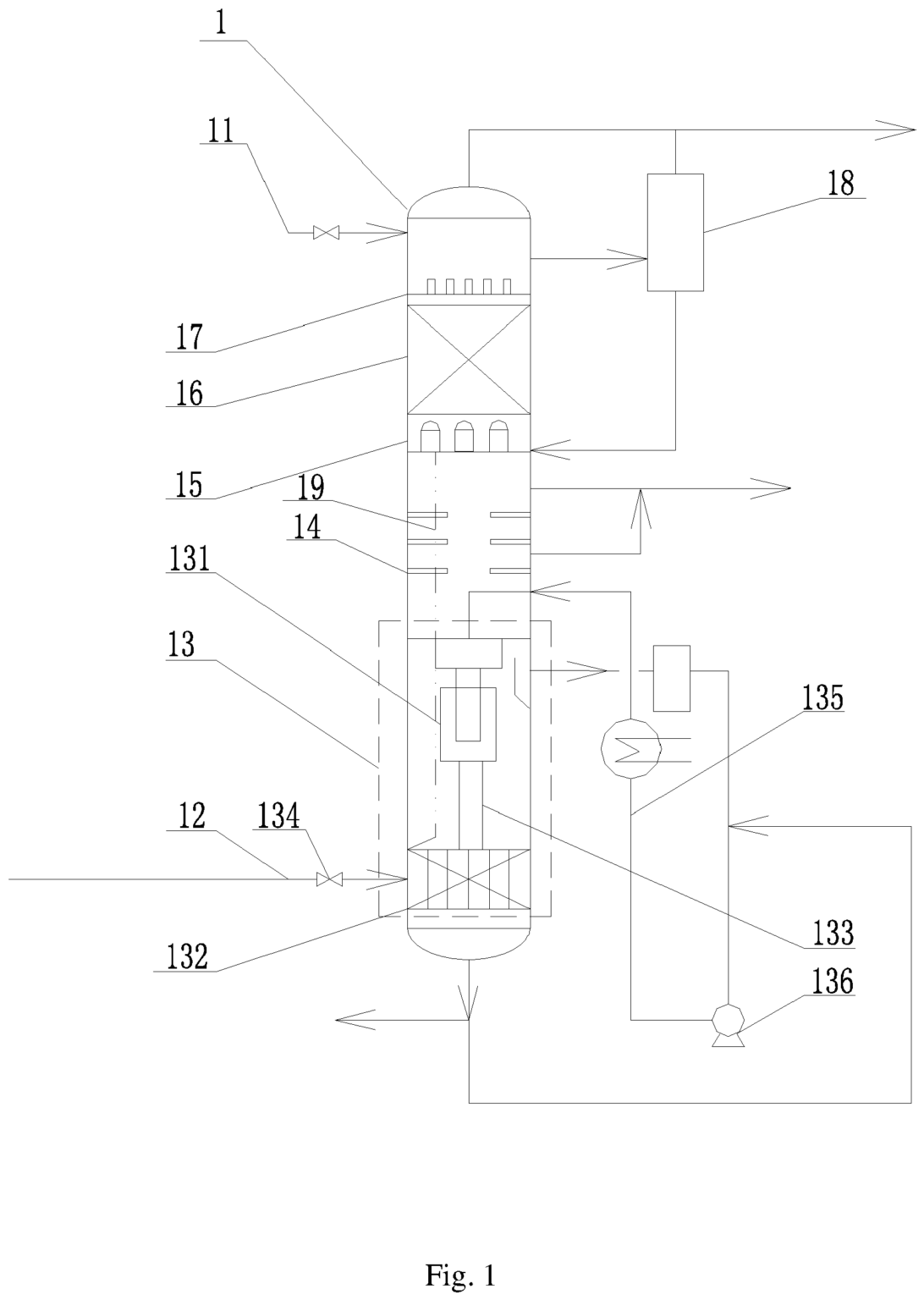

The system incorporates several innovative components, including an oxidation reactor, a liquid phase pipeline for hydrogenated anthraquinone, and a gas phase pipeline for air. The system also features a liquid distributor, a packing section, and a hybrid micro-interface unit consisting of two micro-interface generators.

Features and Improvements

This patented technology stands out for its micro-interface enhanced oxidation system, which includes upper-mounted and lower-mounted micro-interface generators that significantly improve the operational efficiency. The innovative aspect lies in how these generators enable better mixing and dispersion of hydrogenated anthraquinone with air within the reactor, leading to a higher utilization rate of oxygen. This elevates the efficiency of hydrogen peroxide production while occupying minimal space and simplifying the overall operation.

Potential Applications

The advanced oxidation system has several potential applications in industrial settings where hydrogen peroxide is a critical component. Industries such as chemical manufacturing, textiles, paper and pulp, and environmental management can benefit greatly from this efficient and compact system. The