With regulatory approval secured from the Inner Mongolia Energy Bureau, China has officially authorized the development of its first inter-provincial green hydrogen pipeline—a 400km conduit that will deliver 100,000 tonnes of green hydrogen annually from Ulanqab in Inner Mongolia to Sinopec’s Yanshan petrochemical facility in Beijing.

This infrastructure project forms the backbone of a broader strategy to slash hydrogen transport costs, expand domestic use, and shift from demonstration-scale to commercial deployment of green hydrogen. By linking resource-rich Inner Mongolia with a major industrial center, the pipeline serves as a national pilot for what Chinese authorities call the “production-storage-transport-use” hydrogen value chain.

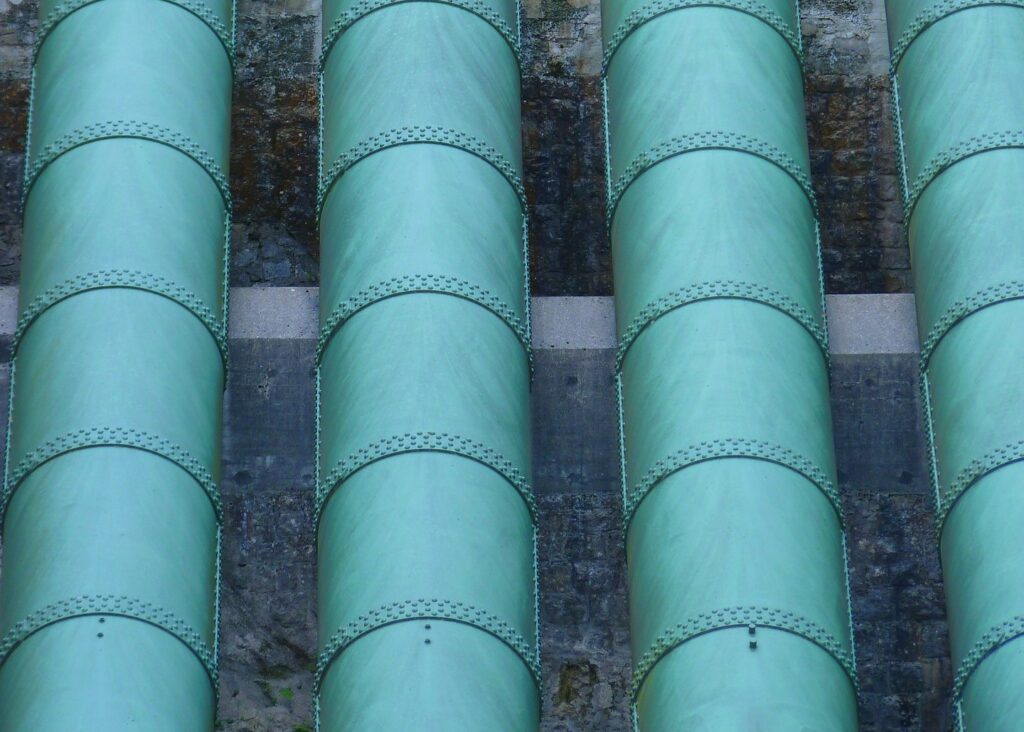

The green hydrogen will be generated from Sinopec’s ¥20 billion ($2.8 billion) renewable hydrogen complex in Ulanqab, which integrates 1GW of wind and solar power capacity with electrolysis. When completed, the facility is expected to become one of the largest of its kind globally, supplying hydrogen at industrial scale for fuel, chemical feedstocks, and mobility applications.

From a logistics perspective, the project represents a strategic leap. While China previously approved a longer 737km hydrogen pipeline within Hebei province in December 2023, this new cross-provincial route is the first to physically connect a renewable hydrogen production base to a major demand center over state-scale distances. It sets a precedent for future national-scale hydrogen networks, and significantly reduces the cost penalty associated with transporting hydrogen via trucks or cryogenic containers.

The Inner Mongolia government has positioned itself as a frontrunner in the national hydrogen race, issuing China’s first provincial hydrogen pipeline development blueprint. The plan envisions a multi-node network of trunk lines, interprovincial loops, and export corridors to support both domestic and cross-border hydrogen flows. This regional approach aligns closely with China’s dual carbon goals—peak emissions by 2030 and carbon neutrality by 2060—by leveraging Inner Mongolia’s abundant wind and solar potential.

The Yanshan terminus is not incidental. Sinopec’s facility there is a sprawling petrochemical complex that produces nearly 100 different oil-based products. The ability to inject green hydrogen into such a hard-to-abate industrial process opens avenues for carbon intensity reduction not just through fuel switching, but also via green ammonia and methanol synthesis. These chemical derivatives are increasingly seen as enablers of hydrogen trade and decarbonization across sectors.

Technological enablers are also falling into place. Earlier work by PipeChina has validated the feasibility of high-pressure hydrogen transmission in long-distance pipelines, easing longstanding concerns around material integrity and leakage risks. These advances are crucial as China begins to pivot from localized pilot projects to scaled regional systems.

Stay updated on the latest in energy! Follow us on LinkedIn, Facebook, and X for real-time news and insights. Don’t miss out on exclusive interviews and webinars—subscribe to our YouTube channel today! Join our community and be part of the conversation shaping the future of energy.