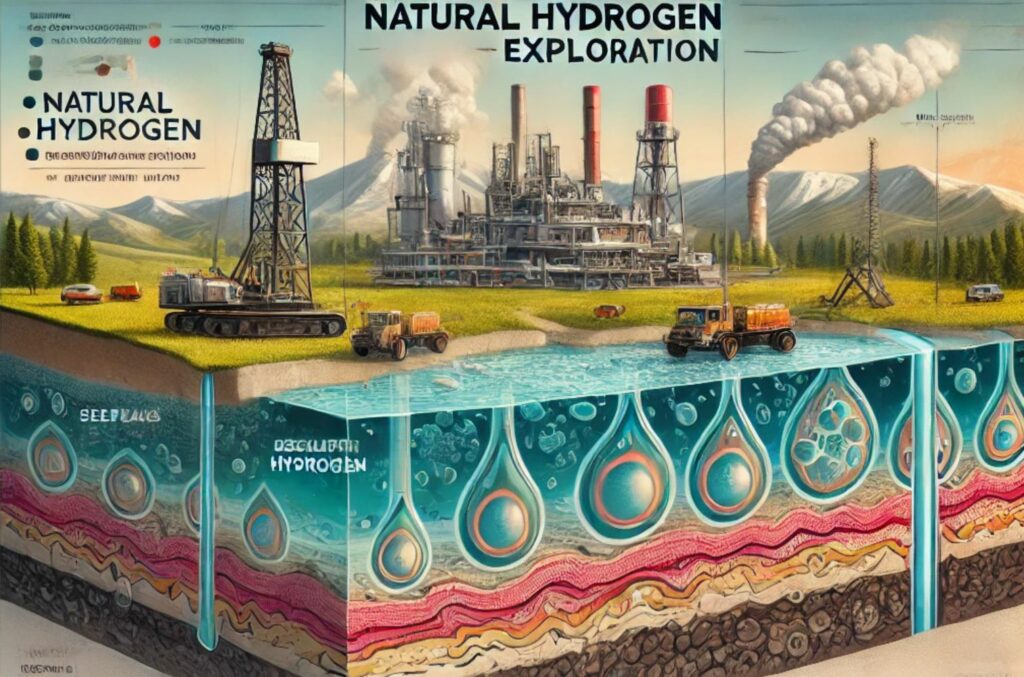

Natural hydrogen exploration is gaining traction as the energy sector seeks sustainable alternatives to fossil fuels.

WATCH THE WEBINAR

This article delves into the three primary play types identified in natural hydrogen systems: focused seepage areas, coal-associated hydrogen, and reservoir-trap-seal configurations. By examining these types critically, we uncover their commercial viability, resource density, and development challenges, providing insights into their potential role in the energy transition.

Focused Seepage Areas: Opportunistic Yet Limited

Focused seepage areas represent settings where hydrogen migrates through subsurface pathways such as faults or fracture zones, often without significant trapping. These seepages may show high hydrogen flux at specific locations, making them attractive for exploration. The most notable example is the Bouraboui field in Mali, where hydrogen flows were detected at rates of 1,500 cubic meters per day during testing.

However, this play type faces significant limitations:

- Resource Nature: Hydrogen in these systems is often dissolved in formation water rather than existing as free gas. As a result, production relies on pressure drawdown to release hydrogen from the solution, akin to opening a carbonated beverage bottle.

- Recovery Rates: Recovery is inherently low, with a typical depletion radius of just a few hundred meters. Calculations from Bouraboui suggest a resource density of approximately 3,000 tons of hydrogen per square kilometer, with a recovery factor as low as 6% under optimal conditions.

- Scalability: Meeting industrial hydrogen demands, such as 300,000 tons per year for an ammonia plant, would require drilling hundreds of wells and managing massive water production volumes. For instance, a single fueling station would necessitate the development of 60 square kilometers of resource area.

While focused seepage areas may be viable for localized or small-scale applications, their limitations in scalability and recovery make them ill-suited for large-scale industrial use.

Coal-Associated Hydrogen: Absorption and Extraction Challenges

Coal seams, long known for their ability to adsorb methane and carbon dioxide, also can store hydrogen. This play type has garnered interest following reports of hydrogen-rich gas in coal seams, such as the Lorraine Basin in France. The hydrogen fraction in these systems typically ranges from 10% to 20%, with the remainder being predominantly methane.

Key characteristics include:

- Resource Density: Coal-associated systems exhibit higher resource densities than seepage plays. Calculations for the Lorraine Basin indicate a potential recovery of 5,500 tons of hydrogen per square kilometer, based on absorption isotherms and coal seam properties.

- Production Rates: Despite higher resource density, production rates per well are constrained. Typical rates are in the range of 40 tons of hydrogen per year per well, which is insufficient for meeting industrial-scale requirements.

- Well Density and Complexity: Effective pressure drawdown requires closely spaced wells—approximately 24 wells per square kilometer for a multi-seam development. This high well density increases operational complexity and costs.

- Gas Separation: Extracted gas mixtures require advanced separation technologies to isolate hydrogen from methane. Current methods are expensive and not optimized for low-pressure systems.

Coal-associated hydrogen plays offer better resource density but face substantial technical and economic hurdles. They are unlikely to serve as standalone solutions but may complement methane extraction in coalbed methane projects.

Reservoir-Trap-Seal Configurations: High Potential, High Uncertainty

Reservoir-trap-seal configurations represent the most promising play type for natural hydrogen. Analogous to conventional natural gas fields, these systems involve trapped hydrogen gas in porous reservoirs sealed by impermeable cap rocks. A speculative example is the Monzon-1 well in Spain, where hydrogen gas shows were reported beneath a thick evaporite seal.

Key advantages include:

- High Recovery Factors: Gas expansion serves as the primary recovery mechanism, enabling substantial well flow rates and efficient resource extraction.

- Commercial Scalability: Unlike seepage or coal-associated plays, reservoir configurations can potentially meet industrial-scale demands if large accumulations are proven.

However, significant challenges remain:

Exploration Risk

Proving the existence of such accumulations requires extensive drilling and pressure testing. Many reported hydrogen shows are ambiguous, lacking definitive evidence of large, trapped volumes.

Seal Integrity

The effectiveness of cap rocks in retaining hydrogen over geological timescales is not well understood, raising questions about resource longevity.

Despite these uncertainties, reservoir-trap-seal plays offer the best chance of achieving commercial viability. Continued exploration and testing are crucial to unlocking their potential.

Comparative Insights

When comparing these play types, a clear hierarchy emerges. Focused seepage areas, while intriguing, are constrained by low recovery and scalability. Coal-associated hydrogen offers higher resource density but is hampered by technical and economic barriers. Reservoir-trap-seal configurations stand out as the most viable option for large-scale hydrogen production, provided exploration challenges can be overcome.

The future of natural hydrogen lies in advancing our understanding of these play types, optimizing extraction technologies, and aligning them with market needs. Only by addressing these challenges can natural hydrogen transition from a geological curiosity to a cornerstone of the energy landscape.

Stay updated on the latest in energy! Follow us on LinkedIn, Facebook, and X for real-time news and insights. Don’t miss out on exclusive interviews and webinars—subscribe to our YouTube channel today! Join our community and be part of the conversation shaping the future of energy.