A new patent by Duiker Combustion Engineers B.V. elaborates on an innovative process for efficiently producing hydrogen through the thermal reforming of ammonia.

Thermal Reforming of Ammonia

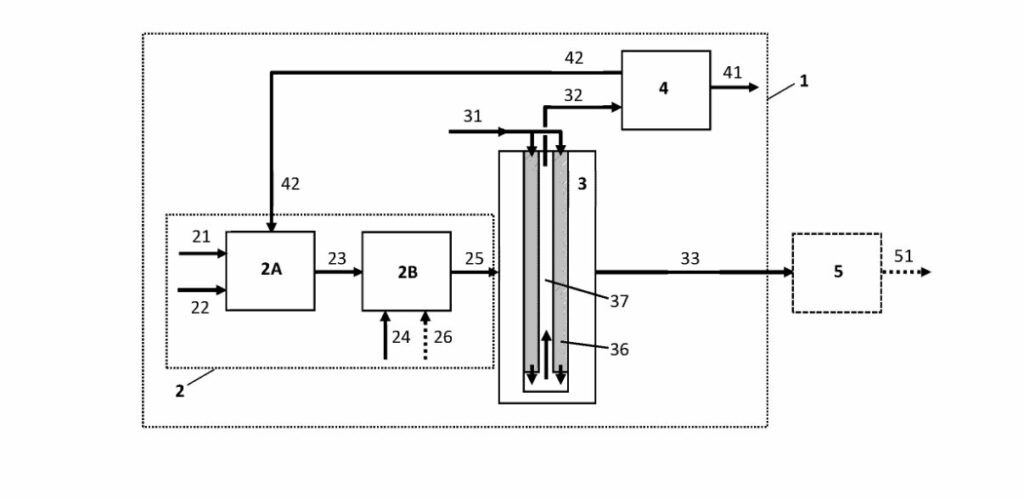

The patented process revolves around the thermal reforming of ammonia to extract hydrogen. The method utilizes an ammonia cracking reactor paired with a catalyst chamber and a staged combustion unit. The catalytic cracking of ammonia is central to this process, enabling the production of hydrogen from ammonia at elevated temperatures.

Two-Stage Combustion Unit

The process employs a two-stage combustion unit that serves to efficiently manage the heat necessary for cracking ammonia. In the first stage, the combustion of ammonia is incomplete, generating flue gases at a temperature range of 750 to 2000°C, ideally between 1200 to 2000°C. This heat is crucial for the subsequent stages of the process.

Catalytic Cracking Chamber

Following the initial stage, the fuel undergoes complete combustion in the second stage, producing a flue gas stream at a temperature lower than the first stage but still significantly elevated. This flue gas is then used to indirectly heat the catalyst chamber in the ammonia cracking reactor. The goal is to achieve a catalytic cracking temperature between 400 to 1000°C, with an optimal range of 600 to 800°C.

Maximizing Hydrogen Yield

Once the ideal catalytic temperature is reached, the ammonia stream is subjected to the catalytic cracking process, resulting in a thermally cracked stream. This stream is then separated into a reject gas stream and an enriched hydrogen stream, with the latter being the desired product. The method ensures that the temperature aids in efficient cracking while maintaining the integrity of the apparatus.

The Significance of Temperature Control

Central to this patent is the meticulous control of temperatures at various stages. The inventors have defined specific temperature relationships between the stages to ensure maximum efficiency in hydrogen production. Specifically, the temperature of the second flue gas stream (T3) must be at least 50°C above the catalytic cracking temperature (T2) up to a limit, and at least 50°C below the first flue gas stream’s temperature (T1).

Exploring New Frontiers in Hydrogen Production

This patent represents a promising step forward in clean energy technology, providing an effective methodology for hydrogen extraction from ammonia. As global energy strategies increasingly lean towards sustainable solutions, this process could play a significant role in the broader adoption of hydrogen as a clean fuel. While still in the conceptual phase, the development of such technologies illustrates the innovative pathways being explored in the quest for sustainable energy.