Siemens Energy Global GmbH & Co. KG has ventured into the realm of chemical reactor design with a new patent aimed at revolutionizing hydrogen production.

This invention outlines a sophisticated reactor setup that incorporates a novel material composition intended to enhance durability and efficiency.

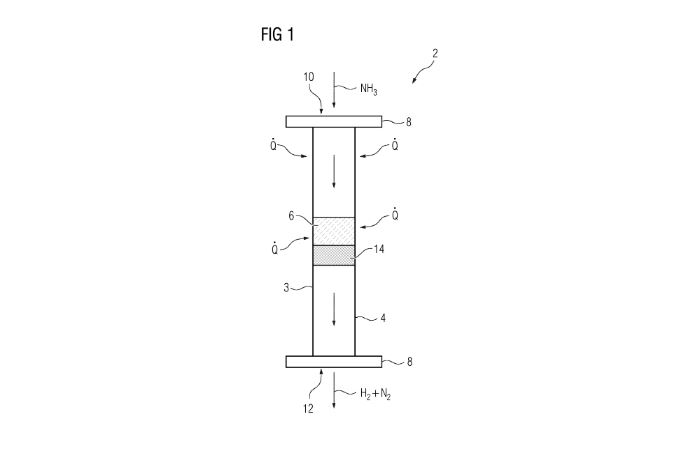

At the heart of this patented technology is a tubular reactor vessel. This vessel is designed to hold a catalyst in the form of a ceramic bed. The patent emphasizes the use of a specific type of material for the vessel: silicon-infiltrated silicon carbide (SiSiC). This choice of material is critical as it addresses common challenges faced in industrial reactor operations.

One of the standout features of this invention is the increased corrosion resistance offered by the use of silicon-infiltrated silicon carbide. This material is known for its exceptional durability when exposed to various corrosive media. By utilizing SiSiC, the reactor vessel is less prone to degradation, ultimately extending the vessel’s service life. This is a significant advancement for the chemical industry, where reactor longevity is a major concern.

While hydrogen generation is a primary focus of this reactor, the design allows for the production of at least one additional product from the reactants. This versatility adds a layer of efficiency and practicality, making the reactor suitable for a range of applications in different industrial settings. The flexibility to simultaneously produce multiple outputs could provide economic advantages as well.

The ceramic bed catalyst housed within the tubular reactor vessel plays a critical role in facilitating the chemical reactions necessary for hydrogen production. The use of a ceramic bed supports a stable and effective reaction environment, ensuring optimal interaction between the reactants and catalyst. This design choice underscores the importance of controlled and efficient chemical processes in the pursuit of sustainable energy solutions.

Stay updated on the latest in energy! Follow us on LinkedIn, Facebook, and X for real-time news and insights. Don’t miss out on exclusive interviews and webinars—subscribe to our YouTube channel today! Join our community and be part of the conversation shaping the future of energy.