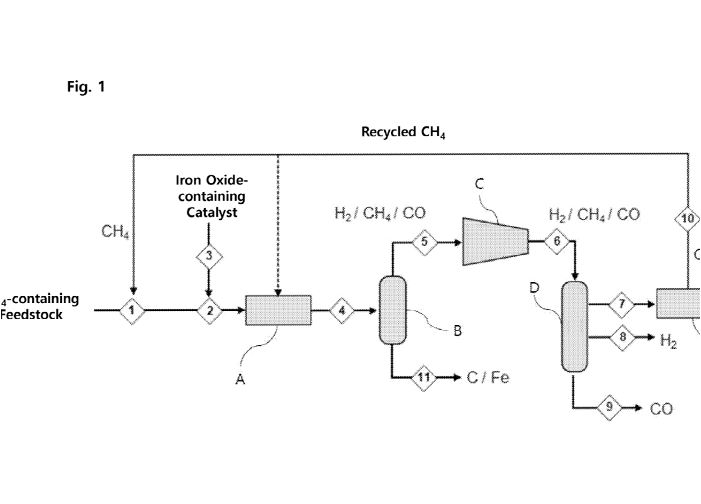

The recent patent filed by SK Innovation Co., Ltd. describes a single, efficient process for generating hydrogen, carbon monoxide, and carbon from methane.

This method stands out because it not only streamlines production but also integrates separation and recovery of the products in a rotary kiln-type reactor.

Central to this innovation is the use of a pyrolysis route which allows the decomposition of methane in the presence of an iron-based catalyst. Pyrolysis is a thermochemical process that facilitates the breakdown of methane molecules, leading to the formation of valuable gases like hydrogen and carbon monoxide. What makes this approach unique is its dual output; both gas and solid products are formed simultaneously, which can be advantageous for various industrial applications.

The iron-based catalyst plays a crucial role in this process. It not only accelerates the chemical reactions involved in breaking down methane but also aids in the formation of solid carbon as a by-product. The catalyst boosts the efficiency of the reactions, leading to a more concentrated production of hydrogen and carbon monoxide. Additionally, the catalyst itself is recovered as a solid product, ready to be reused in subsequent reactions.

Operating at the heart of the process is the rotary kiln-type reactor, designed to handle the pyrolysis of methane efficiently. Auto-thermal reduction implies that the process is self-sustaining in terms of energy balance, utilizing the exothermic and endothermic reactions together to maintain optimal temperatures. This feature not only enhances the efficiency of the conversion process but also reduces the external energy required, making it a potentially cost-effective solution.

An integral aspect of the patented process is the separation and recovery of the products formed. The system is designed to effectively segregate the gaseous products, hydrogen and carbon monoxide, from the solid products, including carbon and the iron-based catalyst. This aspect is crucial for industrial applications where the purity and quality of the hydrogen produced play a significant role.