Daido Steel Co., Ltd, a prominent material science player, has recently filed a patent for a martensitic stainless steel material designed specifically for hydrogen gas environments. The patent, filed on June 27, 2024, outlines a composition and structural design that offers significant advancements over existing stainless steel materials.

The patented material boasts a meticulously balanced chemical composition that enhances its performance in hydrogen gas environments. Key components of this composition include carbon (C), silicon (Si), manganese (Mn), phosphorus (P), sulfur (S), copper (Cu), chromium (Cr), nickel (Ni), and nitrogen (N). Additionally, the material may contain molybdenum (Mo), vanadium (V), niobium (Nb), lead (Pb), and boron (B).

Features:

– Precipitate Content: A minimum of 1.50 mass percent.

– Crystal Grain Size: Prior austenite grain size number of 2.0 or larger.

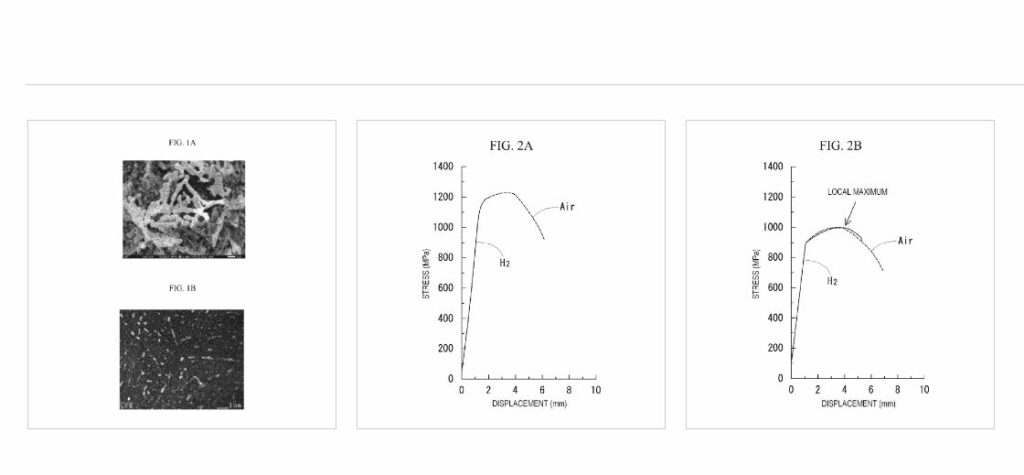

– Martensitic Structure: The material includes a robust martensitic structure.

– Tensile Strength: The tensile strength of up to 1,800 MPa.

– Hydrogen Compatibility: A diffusion coefficient ratio DH2(0.7)/Dair of 0.8 or more indicates excellent performance in hydrogen environments.

Potential Applications

The innovative material is poised to find applications in various hydrogen-related domains, including:

– Hydrogen Storage Tanks: Ensuring the integrity and longevity of storage solutions under high-pressure hydrogen conditions.

– Fuel Cells: Contributing to the durability and efficiency of hydrogen fuel cells in automotive and stationary applications.

– Pipeline Systems: Enhancing the reliability and safety of hydrogen transport infrastructure.

Market Impact

Introducing this advanced martensitic stainless steel material could be a game-changer in the hydrogen market. By addressing the specific challenges associated with hydrogen embrittlement and high-pressure environments, Daido Steel’s innovation promises to improve safety and performance standards. This could accelerate the adoption of hydrogen technologies, subsequently bolstering market growth.

Competitive Analysis

Compared to existing solutions, this patented material by Daido Steel offers several competitive advantages:

– Superior Strength and Durability: The tailored composition and martensitic structure provide better performance under stress.

– Enhanced Hydrogen Compatibility: With a high diffusion coefficient ratio, the material outperforms traditional stainless steels in hydrogen environments.

– Versatility: The material’s robust attributes make it suitable for a range of hydrogen applications, unlike many existing materials limited by their compatibility and strength.

Technical Specifications

The patent details specific mass percentages for each component, ensuring precise chemical composition. For instance:

– Carbon (C): 0.03-1.20 mass percent

– Silicon (Si): ≤1.00 mass percent

– Manganese (Mn): ≤1.50 mass percent

– Chromium (Cr): 8.0-22.0 mass percent

– Nickel (Ni): ≤1.00 mass percent

Furthermore, optional elements such as molybdenum and vanadium may be included to enhance certain properties. Including a martensitic structure is instrumental in achieving high tensile strength and robustness.

Key Takeaways

Daido Steel Co., Ltd’s patent for a martensitic stainless steel material designed for hydrogen gas environments marks a significant technological advancement. The material’s precise chemical composition and superior mechanical properties position it as a promising solution for overcoming the challenges associated with hydrogen applications.