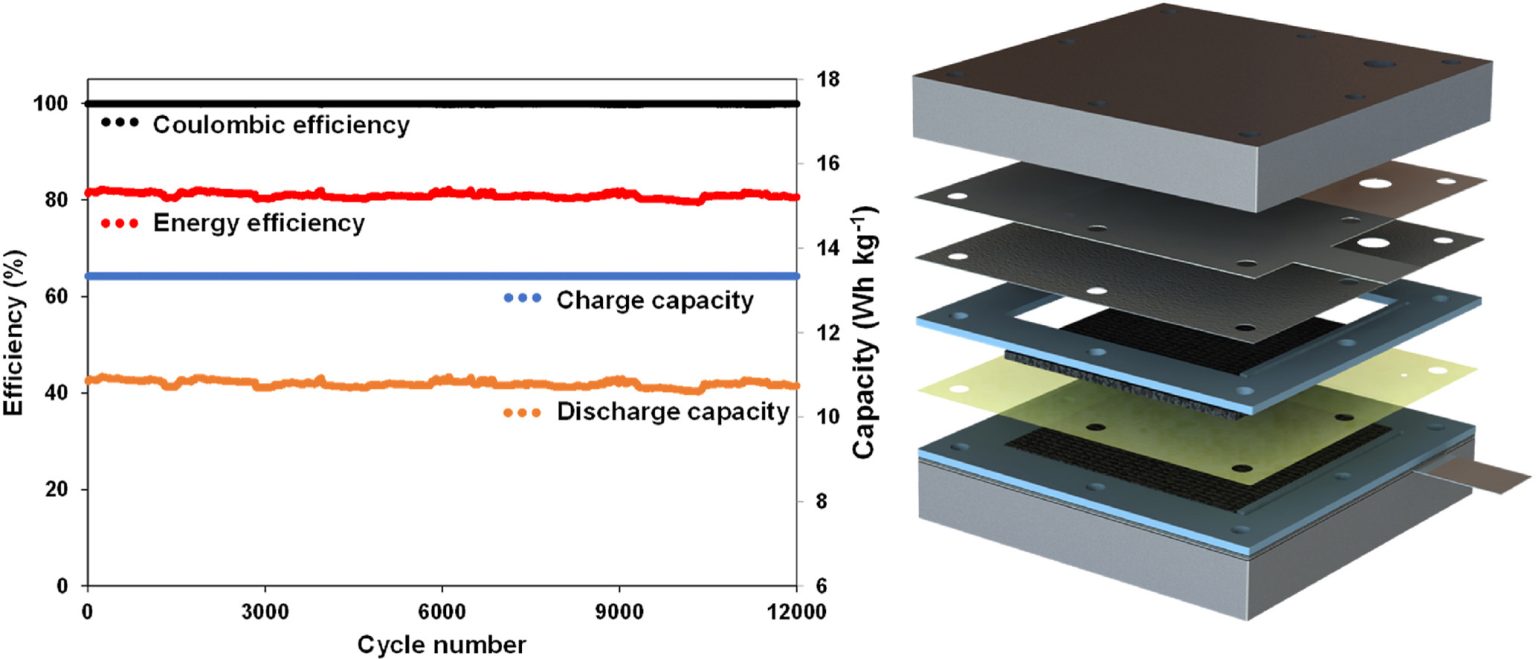

12,000 cycles at 20C-rate with 99.2% capacity retention—the performance metric redefining durability for grid-scale batteries.

The global push toward renewable energy integration faces a critical bottleneck: intermittency management. As grids worldwide strain under the variability of solar and wind, vanadium ion batteries (VIBs) emerge with electrochemical properties tailored to solve grid-scale storage paradoxes. Unlike lithium-ion counterparts, VIBs leverage aqueous vanadium electrolytes and carbon electrodes to achieve unprecedented cycling stability and endothermic charging—a revelation for safety-critical infrastructure.

The Grid Storage Trilemma: Efficiency, Durability, Safety

Grid operators confront a harsh reality: today’s dominant storage technologies force tradeoffs no decarbonizing grid can afford. Lithium-ion batteries, while energy-dense, suffer from thermal runaway risks and rapid degradation at high cycling rates. Vanadium redox flow batteries (VRFBs) offer a longer lifespan but plateau at 70–85% round-trip efficiency with frequent maintenance needs. Sodium-sulfur systems operate at extreme temperatures, complicating deployment.

- Efficiency Penalties: VRFBs lose >15% energy per cycle due to pump loads and ion crossover.

- Cycling Limits: Lithium iron phosphate (LFP) retains ~75% capacity after 5,000 cycles—inadequate for daily-grid buffering.

- Thermal Risks: 23 grid-scale lithium fires were documented globally in 2023 alone.

VIBs disrupt this landscape with an integrated liquid/solid electrode architecture. By eliminating external pumps and enabling proton-selective membranes, they achieve 98.1% round-trip efficiency at 1C-rate—surpassing VRFBs by 13–28 percentage points. At 20C-rate (full charge/discharge in 3 minutes), efficiency remains at 81% with negligible temperature fluctuation (±1.5°C).

Technical Innovations: Beyond Electrochemistry

The VIB’s performance stems from material and design synergies:

- Electrothermal Coupling: Endothermic charging absorbs heat, reducing cooling loads. During 20C-rate testing, temperatures dropped by 1.2°C during charge, while discharging increased by only 1.5°C—a self-regulating thermal profile.

- 0V Discharge Tolerance: Unlike lithium-ion systems, VIBs withstand full discharge to 0V without degradation. This simplifies battery management systems (BMS) and enables safer transport/storage.

- Localized Ion Transport: Carbon felt electrodes facilitate vanadium ion reactions without forced convection, slashing parasitic losses.

Table 1: Performance Benchmarking of Grid Storage Technologies

| Technology | Round-Trip Efficiency (%) | Cycle Life (Retention %) | Thermal Behavior |

|---|---|---|---|

| Vanadium Ion (VIB) | 98.1 (1C) → 81.0 (20C) | 99.2% @ 12,000 cycles | Endothermic charge |

| VRFB | 70–85 (0.1–1C) | 64% @ 500 cycles | Requires active cooling |

| LFP Lithium-ion | 85–95 (0.1–1C) | 75% @ 5,000 cycles | Exothermic; fire risk |

| Lead-Acid | 65–85 (0.1–1C) | 80% @ 400 cycles | Acid leaks; thermal issues |

Scaling Hurdles: Energy Density and Temperature Sensitivity

Despite breakthroughs, VIBs face material limitations. Energy density remains constrained at 13.3 Wh/kg—significantly below lithium-ion’s 150–250 Wh/kg. This necessitates larger footprints for equivalent storage capacity. Temperature dependency also poses challenges: at -15°C, efficiency drops to 84.3% due to electrolyte viscosity increases.

Table 2: Operational Constraints of VIB Technology

| Parameter | Performance | Grid-Scale Implication |

|---|---|---|

| Energy Density | 13.3 Wh/kg | Larger land use per MWh stored |

| Temp Range (Optimal) | 25–35°C | Insulation/heating needed in cold climates |

| Vanadium Concentration | 1.7M (Current) | Higher concentrations untested |

Real-world pilots are now critical. While Siemens/Fluence deploys lithium-based storage in island grids like Madeira 10, VIBs require validation in multi-MW installations. Their 0V discharge tolerance could simplify modular systems, but ion crossover management at scale remains unproven.

The Sustainability Calculus: Emissions vs. Durability

VIBs’ 12,000-cycle lifespan—tripling lithium-ion’s typical 4,000 cycles—reduces replacement frequency and embedded carbon. However, vanadium extraction carries environmental costs: 16 kg CO₂/kg vanadium vs. 9 kg CO₂/kg lithium. Still, the longevity advantage may offset this: over 30 years, VIBs could emit 40% less CO₂/MWh cycled than LFP systems when accounting for manufacturing.

Multi-criteria analysis frameworks (e.g., Fermatean fuzzy SWARA-TOPSIS) now quantify such tradeoffs for EU energy transitions. These tools weigh factors like land use, justice implications, and mitigation costs—dimensions where VIBs’ safety and recyclability may outperform mining-intensive alternatives.

Path Forward: Integration Over Ideology

VIBs won’t replace lithium-ion for EVs or rooftop solar. Their niche is high-cycling grid services: frequency regulation, renewable smoothing, and black-start support. With 288.8 kWh/kg throughput over 12,000 cycles, they outlast alternatives in applications demanding daily, deep-cycling.

As grids evolve toward distributed resilience, VIBs offer a durable, failsafe piece of the storage mosaic. Their breakthrough redefines the possible—but only if scale-up confronts energy density and temperature limits head-on. For net-zero grids, that’s a tradeoff worth testing.