A recent patent titled “Method for Preparing Hydrogen-Rich Fuel Gas,” filed by the inventors at Changzhou University on May 30, 2024, outlines a novel approach to producing hydrogen-rich fuel gas from aluminum smelting waste residues and biomass.

The method leverages innovative preprocessing and catalytic cracking techniques to optimize hydrogen production efficiency.

Features and Improvements

The patented method introduces several enhancements over existing technologies. It involves:

– Adding aluminum smelting waste residues into a medium strong acid for 2-4 hours, filtering, and baking the obtained precipitate at 300-400°C for 3-6 hours.

– Further processing the residues with weak acid and ultrasonic treatment, followed by centrifugal separation and consistent baking at 400-500°C in an air atmosphere.

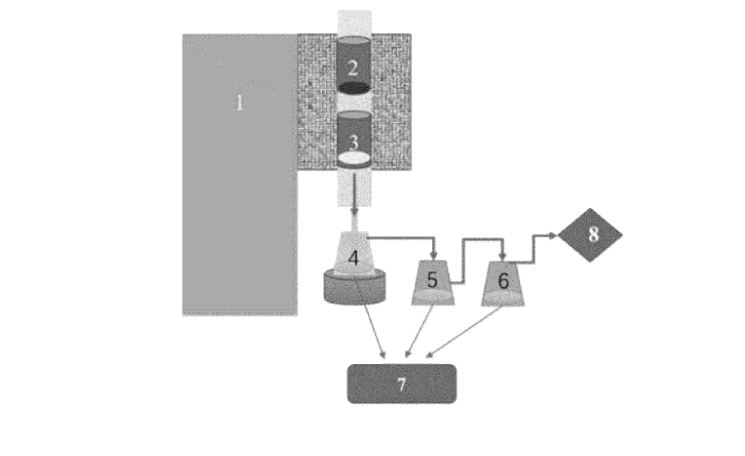

– Utilizing the resultant cracking catalyst in a first-stage pyrolyzing furnace, mixed with biomass at a 1:1 ratio under a nitrogen (N₂) atmosphere and heated to 500-900°C.

– Implementing a second-stage pyrolyzing furnace for secondary catalytic cracking of the initial pyrolysis gas to generate hydrogen-rich fuel gas.

These steps ensure a comprehensive conversion of waste materials into valuable hydrogen fuel, enhancing efficiency and minimizing waste.