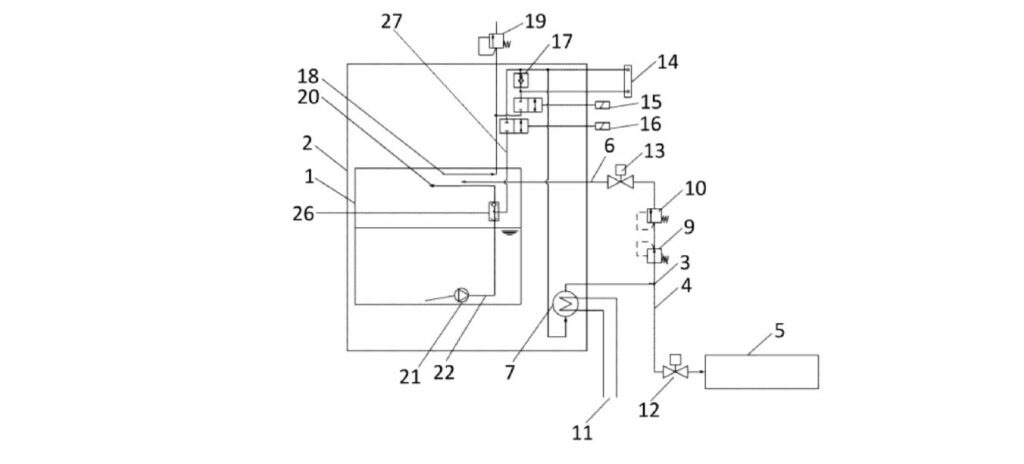

Magna Steyr Fahrzeugtechnik GmbH & Co KG has filed a patent for a cryostorage system designed for storing hydrogen. The system comprises a cryocontainer featuring an inner tank and an outer container, a cryopump located within the inner tank, and a filling interface enhanced with a spring-loaded non-return valve. This setup enables both liquid and gaseous hydrogen to be delivered to consumers at pressures greater than those inside the inner tank.

Features and Improvements

One of the standout features of this cryostorage system is its cryopump arrangement, which facilitates the multi-stage delivery of hydrogen—either in liquid or gaseous form. This system’s configuration allows for hydrogen to be delivered at higher pressures, which is a significant improvement over many existing storage technologies. Additionally, including a spring-loaded non-return valve in the filling interface increases the efficiency and safety of the filling process.

Potential Applications

This patented technology is versatile and can be applied in various sectors:

– Automotive Industry: In hydrogen fuel cell vehicles, efficient and safe hydrogen storage is crucial.

– Energy Sector: For hydrogen storage in renewable energy applications, facilitating better energy storage and utilization.

– Industrial Usage: Industries requiring high-pressure hydrogen for various manufacturing processes.

Comparison with Existing Solutions

Compared to existing hydrogen storage solutions, this patented cryostorage system offers several advantages:

– Efficiency: The cryopump’s multi-stage delivery capability surpasses many current technologies, which typically manage only single-stage delivery.

– Pressure Handling: Storing and delivering hydrogen at higher pressures enables more compact storage solutions and potentially reduces the required storage units.

– Safety Features: The spring-loaded non-return valve adds a critical safety mechanism, reducing the risk of backflow and potential hazards associated with hydrogen storage.

Technical Specifications and Methodologies

Key technical specifications and methodologies described in the patent include:

– Cryopump: Positioned within the inner tank, capable of multi-stage hydrogen delivery.

– Pressure Management: The system delivers hydrogen at pressures greater than those inside the inner tank, facilitating better control and efficiency.

– Filling Interface: The interface includes a spring-loaded non-return valve to enable safer and more efficient filling of the inner tank via the extraction line.

Key Takeaways

Magna Steyr has developed a versatile cryostorage system for hydrogen with key features that improve efficiency, safety, and pressure management.

– Potential applications span across automotive, energy, and industrial sectors.

– The technology presents a significant improvement over existing hydrogen storage solutions, particularly concerning pressure handling and safety features.

– The patented system is poised to make a notable impact on the hydrogen market by potentially reducing operational costs and enhancing adoption rates of hydrogen-based solutions.

By addressing some of the key limitations of current storage solutions, this innovative cryostorage system could play a crucial role in advancing hydrogen technology and its applications in various industries.