The energy sector is continuously evolving, seeking more efficient and sustainable methods for energy production. One innovation contributing to this evolution is a patent filed by EnhancedGEO Holdings for a method that produces hydrogen by thermochemical splitting of water.

This method leverages a subterranean heat source and molten salt to facilitate the chemical reaction, presenting a novel approach to hydrogen production.

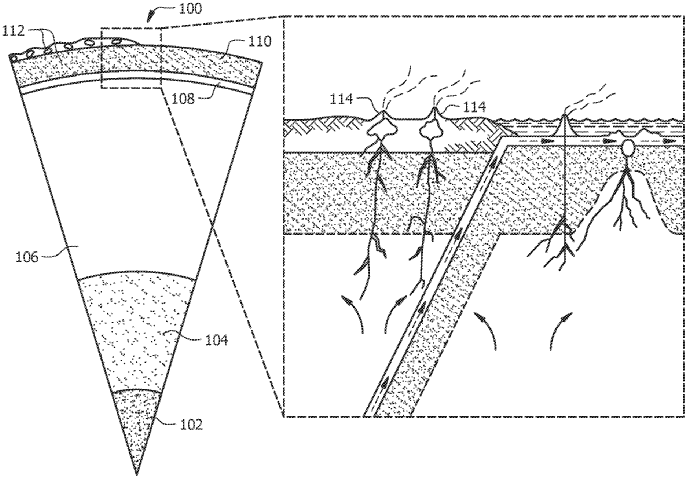

Thermochemical splitting of water is a process wherein water (H2O) is chemically decomposed into hydrogen (H2) and oxygen (O2) using heat. The newly patented method by EnhancedGEO Holdings, LLC brings in an innovative twist to this process by using molten salt heated through a subterranean heat source. The introduction of molten salt as a medium in the reaction chamber provides a consistent and high-temperature environment necessary for the thermochemical reaction to occur efficiently.

Key Components

This patented method incorporates several key components to ensure the efficient splitting of water:

1. Feed Streams: One or more streams of water are injected into a carefully designed reaction chamber.

2. Molten Salt: Heated by a subterranean source, the molten salt is the medium that provides the necessary thermal energy for the reaction.

3. Reaction Chamber: This chamber houses the reaction and facilitates the separation of the resultant hydrogen and oxygen gases.

4. Product Removal: The formed hydrogen and oxygen are systematically removed from the chamber to prevent any interference with the ongoing reaction.

The use of a subterranean heat source is a cornerstone of this method, offering a sustainable and efficient means of heating the molten salt. This heat source can vary from geothermal energy to other sub-surface thermal resources. By harnessing natural subterranean heat, the method not only achieves the required reaction temperatures but also minimizes external energy inputs, thereby enhancing the overall energy efficiency and environmental sustainability of the process.

Applications

Once formed in the reaction chamber, the hydrogen can be utilized in various downstream processes, including the generation of hydrocarbons. The versatile application of the produced hydrogen presents significant potential for industries that rely on hydrogen as a key input for manufacturing chemicals or as a clean fuel. Additionally, by improving the efficiency of hydrogen production, this method could contribute to reducing the carbon footprint associated with energy-intensive industrial processes.