The advancements in material science continue to push the boundaries of what is possible with everyday objects. Today, we explore a unique patent by Denka Company Limited focusing on a ceramic plate designed to have minimal hydrogen emission when subjected to heat.

This innovation has potential implications for a range of industrial applications where low gas emission at high temperatures is crucial.

In various high-tech industries, including semiconductors and aerospace, materials that emit gasses at high temperatures can compromise the integrity of sensitive processes and equipment. Hydrogen, in particular, poses significant challenges due to its reactivity. The new ceramic plate developed by Denka addresses this issue by minimizing hydrogen emission, thereby enhancing operational safety and material performance.

Technical Specifications

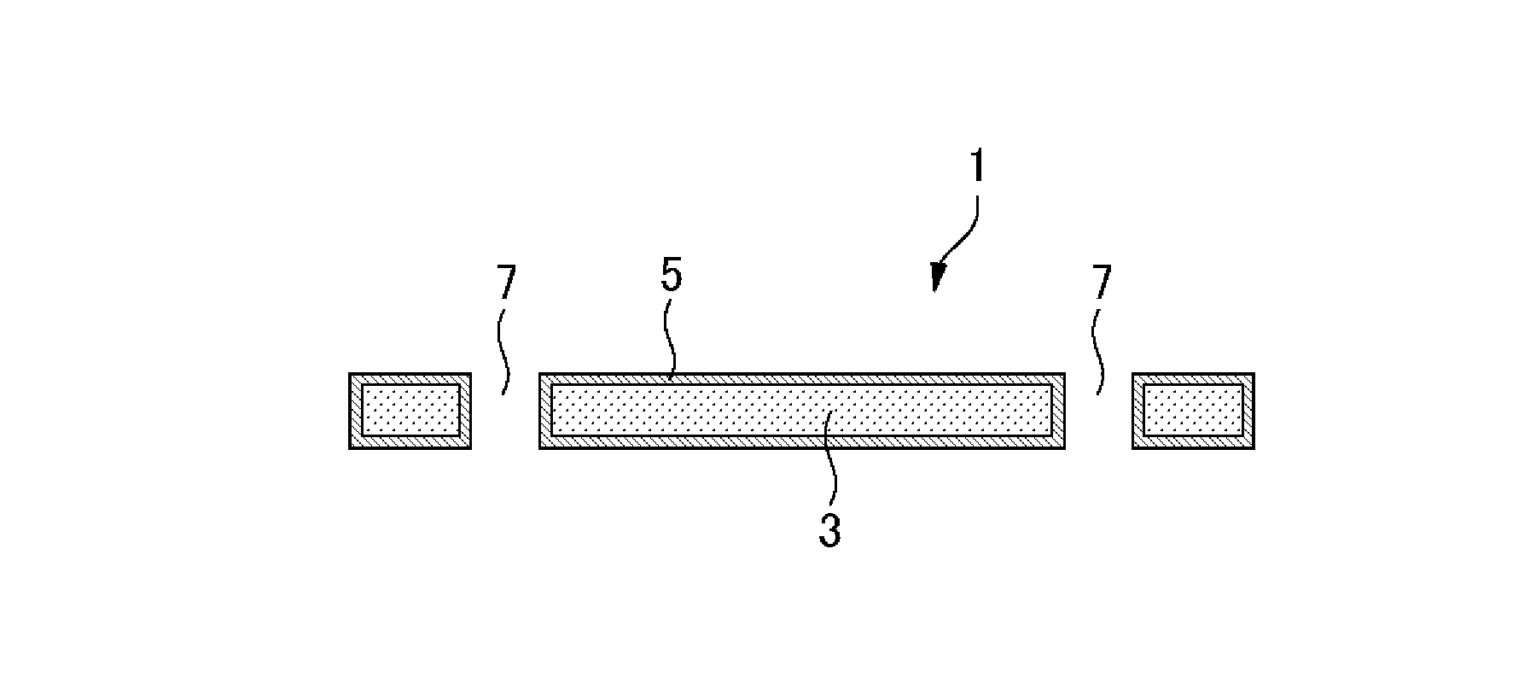

This patented ceramic plate includes a plating film on at least part of a surface of the plate-shaped ceramic member. The performance of this ceramic plate is measured by its hydrogen emission when heated from 25°C to 400°C at a rate of 5°C per minute. The critical parameter here is the amount of hydrogen released per unit mass at 250°C, noted as A250. According to thermal desorption spectrometry measurements, this ceramic plate releases hydrogen at a level of 5.0×10^-10 A/g or less in terms of mass spectrum intensity of ion current value. This exceptionally low emission rate is a testament to the advanced manufacturing techniques employed.

The ceramic plate is fabricated using materials that have undergone specific treatments to ensure minimal release of hydrogen. The plating film not only acts as a protective barrier but also plays a significant role in reducing the hydrogen released when the ceramic material is subjected to heat. Such innovative engineering ensures the material’s suitability for high-stakes environments.

The ceramic plate’s ability to maintain structural integrity and performance by emitting minimal hydrogen makes it suitable for a broad spectrum of applications. In semiconductor manufacturing, for example, low-emission materials are essential to prevent contamination of silicon wafers. Similarly, in aerospace applications, components made of such advanced ceramics can contribute to safer, more reliable operations by reducing the risk of material degradation at high altitudes and temperatures.