The newly filed patent by Linde GmbH discloses a novel approach to operating an electrolysis plant aimed at enhancing the process of converting water into oxygen and hydrogen.

At its core, the invention details a method for optimizing fluid flow within the electrolysis plant, which is fundamental in improving the efficiency and functionality of the system.

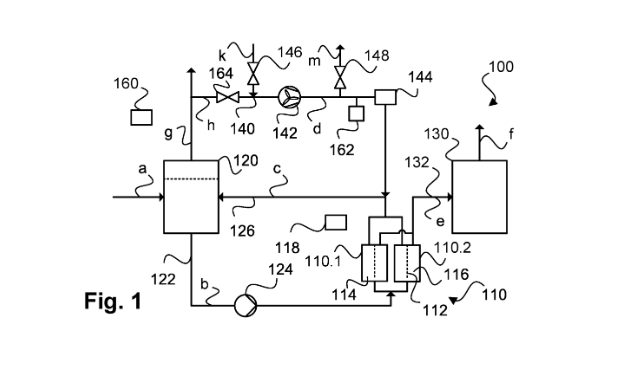

Central to the innovation is the processed fluid flow that emanates from the oxygen side of the electrolysis unit. This fluid flow comprises both water and gas and progresses into a gas separator. Subsequently, an oxygen-containing fluid flow is extracted from the gas separator and regulated back into the oxygen region of the electrolysis plant.

One of the critical elements in this method is the option to manipulate the oxygen-containing fluid flow before it reenters the electrolysis plant’s oxygen region. If the situation demands, ambient air can be integrated into the oxygen-containing fluid flow. This mixing or substitution with ambient air serves as a contingency measure, ensuring that the plant can maintain optimal oxygen levels regardless of varying operational conditions.

Beyond the method, the patent also encompasses a design specification for a corresponding electrolysis plant. This facility is structured to facilitate the described fluid management processes seamlessly, ensuring that all components, from the electrolysis unit to the gas separator and supply points, work cohesively.

Stay updated on the latest in energy! Follow us on LinkedIn, Facebook, and X for real-time news and insights. Don’t miss out on exclusive interviews and webinars—subscribe to our YouTube channel today! Join our community and be part of the conversation shaping the future of energy.