Alkaline electrolyzers have long been a pivotal part of hydrogen production technology, serving as an integral component in the transition to cleaner energy sources.

The newly filed patent by Industrie De Nora S.p.A. presents advancements in this technology, focusing on improvements in the efficiency and operation of alkaline electrolyzers.

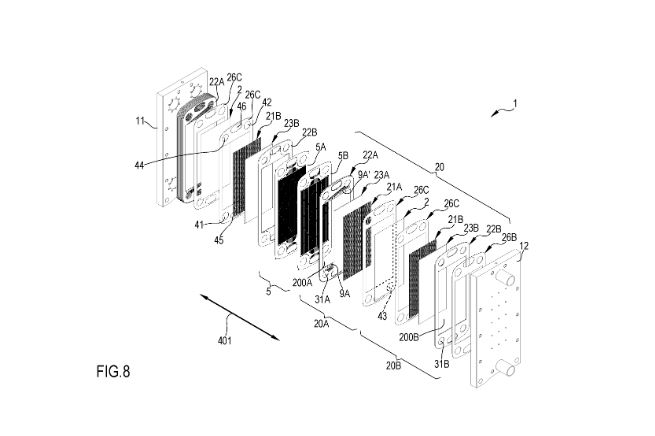

The central focus of the patent lies in the enhancement of bipolar plates used within the electrolyzer. These plates are pivotal as they separate each elementary cell in the stack. According to the patent, each bipolar plate is made up of two components coupled together. This dual-component design plays a crucial role in defining inner cavities meant for the circulation of a cooling fluid. By optimizing the flow of this fluid, the electrolyzer ensures better thermal regulation, contributing to both efficiency and longevity of the equipment.

Enhanced Thermal Management

Effective management of thermal energy is essential in the operation of any electrolyzer, and the invention addresses this by incorporating specified inlet and outlet sections into the design of each bipolar plate. These allow the cooling fluid to circulate efficiently through the cavities, assisting in maintaining an optimal temperature for hydrogen production. The improved thermal management not only enhances performance but also potentially reduces the wear and tear on components, leading to a more sustainable operation.

Safety and Efficiency in Hydrogen Production

By proposing this innovative structure, the patent addresses some longstanding challenges in alkaline electrolyzer design. Effective cooling reduces the risk of overheating, a critical safety concern, and improves overall efficiency. While the electrolyzer continues to operate in the parameter of conventional alkaline electrolytes, these nuanced changes may lead to greater yields and reduced energy consumption.

This patent is a significant step in the evolution of hydrogen production technology. Although its impact can be fully understood only after practical implementation, the introduction of better thermal regulation components could translate into cost savings and enhanced safety measures. As industries increasingly aim for sustainable growth, such technological advancements are poised to become foundational in achieving global energy goals.

Stay updated on the latest in energy! Follow us on LinkedIn, Facebook, and X for real-time news and insights. Don’t miss out on exclusive interviews and webinars—subscribe to our YouTube channel today! Join our community and be part of the conversation shaping the future of energy.