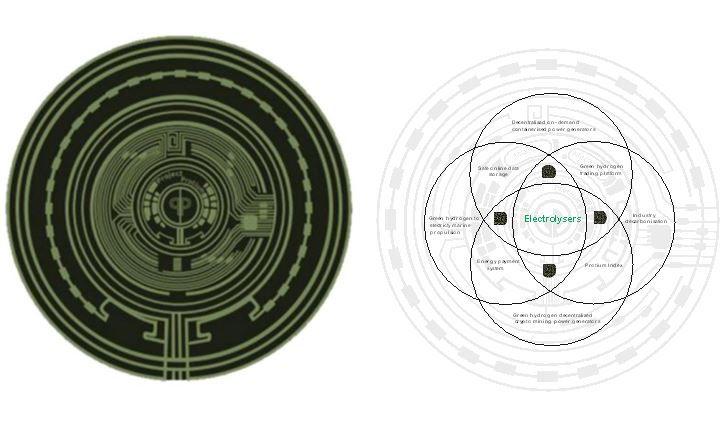

This paper presents a pioneering approach by Project Protium’s electrolyzer which integrates diverse energy forms—magnetic, acoustic, chemical and pulsed electrical energy.

This multifaceted strategy significantly enhances the efficiency of hydrogen production, providing a pathway to overcome traditional limitations associated with electrolysis.

Hydrogen serves as a clean and versatile energy carrier, yet its production through electrolysis often struggles with inefficiencies due to high energy consumption and overpotentials. Conventional electrolysis systems primarily rely on electrical energy, which limits performance. This paper outlines a novel electrolyzer design by Project Protium that employs various energy forms to optimize the electrolysis process, leading to unprecedented efficiency gains.

Forms of Energy in the Project Protium Electrolyzer

1. Magnetic Energy:

– Field Interaction: Magnetics create fields which influences the behavior of charged particles and ions within the electrolyte. This field enhances ion mobility, aligning and organizing ions to promote efficient electrochemical reactions at the electrodes.

– Energy Storage and Release: Although the magnetic field does not convert to usable energy in the same manner as electrical energy, it facilitates electrochemical processes, reducing resistance and lowering energy requirements for the reactions.

2. Acoustic Energy:

The first acoustic system transforms seawater enhancing surface area and facilitating more effective electrolysis. This increases the interaction between the electrolyte and electrodes, improving the efficiency of hydrogen production.

The second acoustic system

– Bond Disruption System: The second acoustic system is strategically placed diagonally to target the electrolyte as it travels upward from the first acoustic system to the electrodes. By using sound waves this system disrupts hydrogen-oxygen bonds with ultrasonic waves, ensuring enhanced dissociation and mass transfer in the electrolyte. Improved interaction between the electrolyte and the electrodes results in higher rates of hydrogen and oxygen evolution.

– Dynamic Pressure Changes: The dual acoustic systems can induce localized pressure variations that dislodge gas bubbles from the electrode surfaces, alleviating mass transfer limitations and further improving system efficiency.

3. Chemical Energy from Catalysts:

– Enhanced Reaction Rates: The electrode composition, when coated with the optimized nanoscale earth-abundant catalyst, lowers the activation energy required for electrochemical reactions. This reduction allows the system to operate effectively at lower voltages, translating to improved energy efficiency.

– Phase Changes: Utilizing phase changes in the catalysts enhances their performance under varying operational conditions, making them more effective in facilitating the necessary reactions for electrolysis.

4. Pulsed Power Input:

– Controlled Energy Delivery: The pulsed power approach allows for more efficient energy delivery compared to continuous power input. This strategy helps maintain optimal conditions at the electrodes and minimizes energy waste.

– Frequency and Duration Effects: By adjusting pulse parameters, the energy input is optimized to match the dynamic requirements of the reactions, further enhancing system performance.

Energy Transformation and Synergy

– Synergistic Effects: The integration of these diverse energy forms creates a synergy that enables the system to perform far beyond conventional electrolysis systems that rely solely on electrical energy and PGM class catalysts.

– Non-linear Relationships: The interactions among different energy forms can yield non-linear benefits, where the combined effect exceeds the sum of individual contributions, particularly in an optimized system like the one presented.