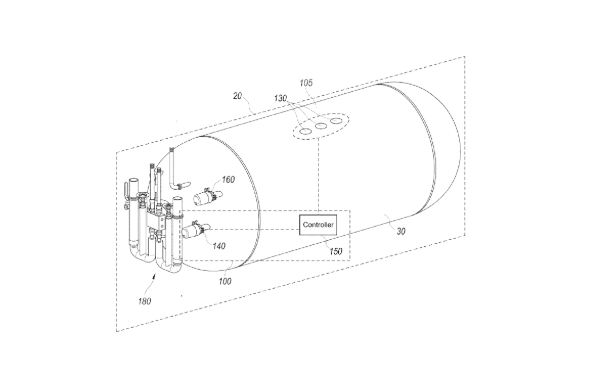

The patent by Universal Hydrogen introduces an innovative active venting control system specifically designed for liquid hydrogen tanks.

This system is a significant advancement in hydrogen storage technology, enabling a more efficient and safe way to store hydrogen for extended periods.

The active venting control system is engineered to actively monitor and manage the pressure and fill level within a hydrogen tank. By integrating an advanced monitoring system, the control system can determine the optimal times to vent hydrogen to maintain safe pressure levels. This active approach contrasts with traditional passive pressure relief systems, offering enhanced control and efficiency.

One of the standout features of this system is its ability to allow a greater mass of hydrogen to be stored safely. By venting the tank when it reaches a predetermined fill level for specific time intervals, the system supports filling tanks with a higher initial fill level. This leads to the storage of a larger quantity of hydrogen compared to conventional methods, which is an essential advancement for industries reliant on hydrogen fuel.

The ability of the active venting control system to repeat the venting process during both transit and storage times is a key benefit. This repetition ensures that tanks can maintain safe pressure levels while achieving higher initial fill levels. The system’s design facilitates better hydrogen management, which can contribute to reduced transportation costs and improved fuel efficiency.

Stay updated on the latest in energy! Follow us on LinkedIn, Facebook, and X for real-time news and insights. Don’t miss out on exclusive interviews and webinars—subscribe to our YouTube channel today! Join our community and be part of the conversation shaping the future of energy.