The highlight of this patent lies in the improvement of ammonia cracking processes specifically aimed at enhancing gas purification.

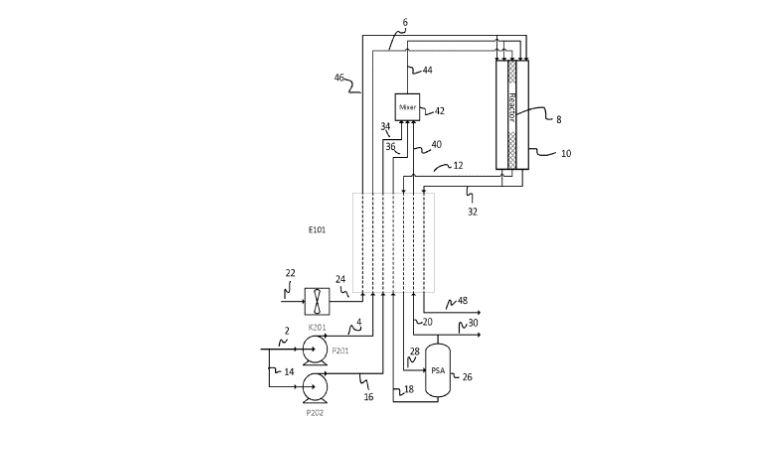

By utilizing a Pressure Swing Adsorption (PSA) system, the process focuses on converting residual ammonia present in the cracked gas into additional hydrogen and nitrogen. The key to this innovation is feeding PSA tail gas, or a gas derived from it, back into a secondary cracking reactor for further processing. This additional step significantly optimizes the purity of the final cracked gas output.

Pressure Swing Adsorption (PSA) systems play a critical role in the purification of gases in various industrial applications. In the context of the ammonia cracking process described in this patent, the PSA system is used to separate and purify the primary cracked gas. Any residual ammonia remaining in the gas can affect its quality and usability, making it essential to find effective methods to eliminate these impurities.

One of the main innovations introduced by this patent is the integration of a secondary cracking reactor. By feeding the PSA tail gas—or gas derived therefrom—back into this reactor, the residual ammonia within the gas is converted into further amounts of hydrogen and nitrogen. This additional conversion step not only makes the process more efficient but also enhances the quality of the final product.

The conversion of residual ammonia to additional hydrogen and nitrogen is a significant advantage introduced by this process. Hydrogen and nitrogen are critical components in various industrial applications, ranging from chemical manufacturing to energy production. By maximizing the yield of these gases, the patented process presents an enhanced method for ammonia cracking that yields higher-quality results.

This ammonia cracking process can offer both environmental and economic benefits. By improving the purity of the gas output and maximizing hydrogen and nitrogen production, industries can achieve better efficiency and potentially lower operational costs. Furthermore, the conversion of residual ammonia into useful gases contributes to reducing waste and minimizing environmental impact.