With the European Union aiming for a 55% reduction in carbon emissions by 2030, industries are increasingly scrutinizing their energy sources. A recent study in the International Journal of Hydrogen Energy examines a novel approach combining high-temperature electrolysis with industrial waste heat to produce green hydrogen on-site. This strategy not only seeks to capitalize on the potential of Solid Oxide Electrolysis Cells (SOEC) but also aims to leverage existing industrial processes to enhance sustainability.

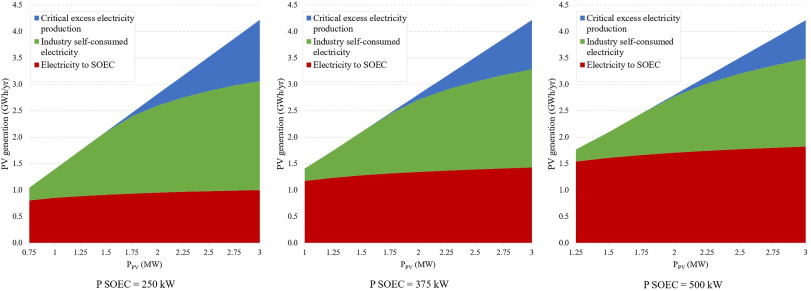

According to the report, the SOEC system utilizes photovoltaic energy coupled with industrial waste heat, effectively optimizing resource use. The Levelized Cost of Hydrogen (LCOH) in the best SOEC configuration is estimated at 6.1 €/kgH2. This cost-effectiveness is crucial, given that current SOEC manufacturing expenses present a barrier to achieving more competitive LCOH rates below 6 €/kgH2. Despite these financial challenges, SOEC systems promise higher thermal efficiency than conventional alkaline electrolyzers.

In the context of industrial application, hydrogen is integrated with natural gas, facilitating a gradual transition in industrial burners. Importantly, this integration requires minimal changes to the existing burner infrastructure due to hydrogen volumetric fractions capped at 20%. This adaptability is crucial for industries seeking less invasive transition methodologies.

The analysis underscores the high efficiency of SOEC systems in reducing carbon emissions when compared to their alkaline counterparts. However, these systems face limitations imposed by cost barriers, and energy crisis-induced high natural gas prices. Nevertheless, these market conditions have inadvertently made the SOEC approach more competitive when gauged against the EU’s emissions trading system.

The potential for cost reductions in SOEC technology, driven by economies of scale and technological advancements, offers a glimpse into a future where green hydrogen production becomes widely accessible. Experts are therefore advised to closely monitor shifts in SOEC production costs alongside natural gas market trends, as these will significantly impact the viability of integrating hydrogen into industrial processes.

The study has also sparked discussion about the need for policy interventions to further facilitate this transition. While technological advancements are crucial, regulatory frameworks that encourage the adoption of hydrogen and support cost-reduction measures are equally imperative. As the industry moves forward, understanding these dynamics will be paramount for stakeholders aiming to position themselves favorably in the shifting landscape of industrial energy consumption.