Bilfinger has been entrusted by Uniper to provide engineering, procurement, and construction management (EPCm) services for an innovative hydrogen project in the Krummhörn cavern storage facility in Lower Saxony, Northern Germany.

The project aims to establish a commercial storage solution for green hydrogen, utilizing Bilfinger’s cutting-edge hydrogen processing technology, “H2DRY.”

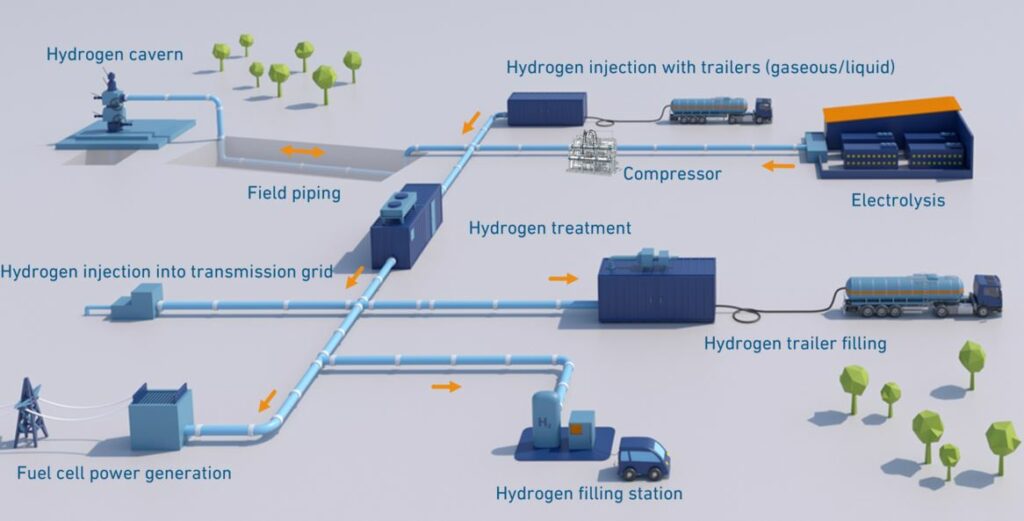

Uniper’s ambitious plan involves the construction of a hydrogen storage facility with a capacity of up to 3,000 m3 in a pilot cavern within the former Krummhörn natural gas storage facility. This endeavor represents a pioneering effort to operate a hydrogen storage facility under real conditions, providing invaluable insights during the two-year test phase. The data gathered will serve as the foundation for broader projects, including the construction of commercial hydrogen caverns.

Bilfinger’s involvement encompasses crucial EPCm services for the above-ground plant technology of the hydrogen test cavern. Renowned for its swift, flexible, and quality-oriented approach, Bilfinger had previously conducted the basic engineering for the project, leading to its selection for the new contract. Thomas Schulz, Group CEO of Bilfinger, expresses pride in supporting Uniper in this groundbreaking initiative, emphasizing Bilfinger’s commitment to sustainable solutions and leveraging its expertise in the gas industry.

The successful realization of hydrogen storage facilities, such as the one in Krummhörn, holds the potential to revolutionize energy supply dynamics. Hydrogen caverns, conceived for storing substantial quantities of green hydrogen, could become integral to meeting future energy demands. Uniper’s Managing Director, Doug Waters, acknowledges the strategic significance of cavern storage facilities, emphasizing the importance of Bilfinger’s support in exploring new frontiers for their pilot project.

A standout feature of this project is the utilization of Bilfinger’s H2DRY technology, a hydrogen drying system developed by the industrial services provider. This technology, currently being tested at another location, Rüdersdorf near Berlin, removes water from hydrogen through absorption. Efficient hydrogen treatment at a large scale becomes possible, addressing concerns of moisture-induced corrosion on pipes or valves.