With some of the most ambitious climate change targets in the world, our renewable energy sector is playing a critical role in decarbonizing our energy system as we work towards achieving net-zero.

The world’s raw resources are limited. As demand for these resources increase, supplies deplete, driving up costs.

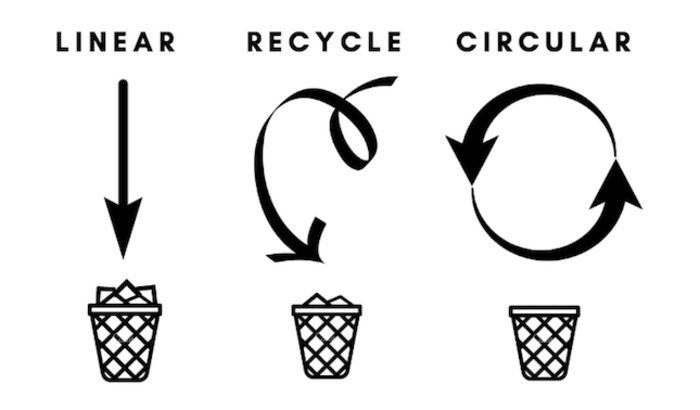

The circular economy represents an opportunity to move away from the linear approach of creating and delivering a product or service that is disposed of at the end of its life.

This waste represents an enormous pool of resources that can be exploited with minimal impact on the environment.

A circular economy focuses on responsible production: businesses which supply products and services get the maximum life and value from the resources used to make them, keeping these resources in a continuous loop of re-use.

Doing that can take a number of forms, from re-use and repair (where a product’s lifecycle is extended by maintenance), remanufacturing (where a product is repurposed at the end of its ‘first life’ to enable further uses), recycling (where products are separated into component parts and materials to be used in new products) or by altering design and manufacturing processes to reduce or eliminate waste.

Adopting a circular approach presents a great opportunity for many sectors across the country – including onshore wind.

As 2030 approaches, a significant number of wind farms will reach the end of their 20-25 year lives. With 80% of a modern wind turbine recyclable, industry is looking at what is next for these turbines and their components.

A number of businesses in onshore wind are already harnessing the opportunities presented by a circular economy.

Wind turbine blades are made of fibreglass or carbon fibre and are complicated to recycle, often ending up in landfill sites once they reach their end of life.

Turbine blade repair specialist Renewable Advice is working to change that. The company is the UK’s leading expert in blade repair, inspection and maintenance.

Highly-skilled blade engineers carry out various refurbishments, ranging from cleaning to large structural repairs. Using innovative techniques, including blade recoating and component replacement, the company is working hard to increase the lifespan of blades and to divert them from landfill. It is also working in collaboration with academia to commercialise recycling of fibreglass for the wind industry, which would offer a long-term solution to reducing blade waste.

It’s not only the environment that benefits from a circular economy.

There is opportunity for businesses to grow and develop by getting the most value out of their resources.

Argyll-based Renewable Parts is one of these companies.

Its business model is wholly shaped around remanufacturing and reusing wind turbine components.

“We feel very strongly about the need to be greener” says Renewable Parts CEO James Barry.

“Wind energy is a green energy source – that fact is well understood. But we must also run the industry in the greenest way possible. This includes recycling materials that are unserviceable and returning them back into market.”

The company works with wind power developers to increase the reuse of component parts from decommissioned wind turbines. These components are then re-entered into the supply chain to be used on other wind farm sites.

By providing both a product and a service, and by getting maximum value out of used turbine components, Renewable Parts develops long-term relationships with its clients, providing them with access to spare turbine parts at a lower cost and with a shorter lead time than a standard supplier.

New organisations emerging into the industry are also developing their business plans to align with the circular economy.

ACT Blade is designing, building, and testing the next generation of wind turbine blades, with circularity at the heart of its manufacturing process.

Using technology adapted from the sailing industry it has designed a blade using a combination of carbon fibre structure and textile, making it partly recyclable.

Using this new material means that the blade is 50% lighter and 30% stronger than a standard fibreglass blade. This lower weight also means that blade length can be increased, boosting the energy produced by more than 9%.

“This ultralight blade has the potential to be completely disruptive to the renewables sector, allowing for substantial cost savings and increased production of wind energy.”

ACT Blade Chief Executive, Dr Sabrina Malpede.

Due to its modularity, this new blade design can be manufactured by existing supply chains at a lower cost, and through a far simpler and faster assembly process.

The circular economy is key part of the solution to our global climate emergency.

Scotland’s onshore wind sector must continue to embrace it and the benefits it can bring to not only the environment but to individual businesses and the people in our communities.

This is not just an opportunity for the energy supply chain to be more sustainable, but to prosper in the future too.

Making used parts a saleable asset at the end of a project’s life will not only help to reduce end-of-life costs but will also play a role in reducing the price of wind energy as demand for raw materials is reduced.

Increased deployment of renewable generation across the country is vital if we’re to meet our net-zero ambitions.

And it is essential that we achieve this using the fewest resources and in the most sustainable way possible.