Hydrogen storage and compression are critical for developing hydrogen as a sustainable energy source. The patent filed by Chevron U.S.A. Inc. outlines an innovative approach to improving the efficiency of hydrogen absorption and desorption using metal hydride composite materials.

This method aims to enhance the practicality and efficiency of hydrogen storage systems, pivotal for various applications, including fuel cells and hydrogen-powered vehicles.

The Problem with Conventional Systems

Traditional hydrogen storage systems often face challenges related to the slow rates of hydrogen absorption and desorption, ultimately affecting their efficiency and usability. The central bottleneck lies in heat management. Efficient heat transfer is crucial because the processes of absorbing hydrogen (endothermic) and releasing it (exothermic) involve significant thermal changes. Without efficient heat transfer mechanisms, hydrogen storage systems can become inefficient and impractical for many applications.

Innovative Solutions for Heat Transfer Enhancement

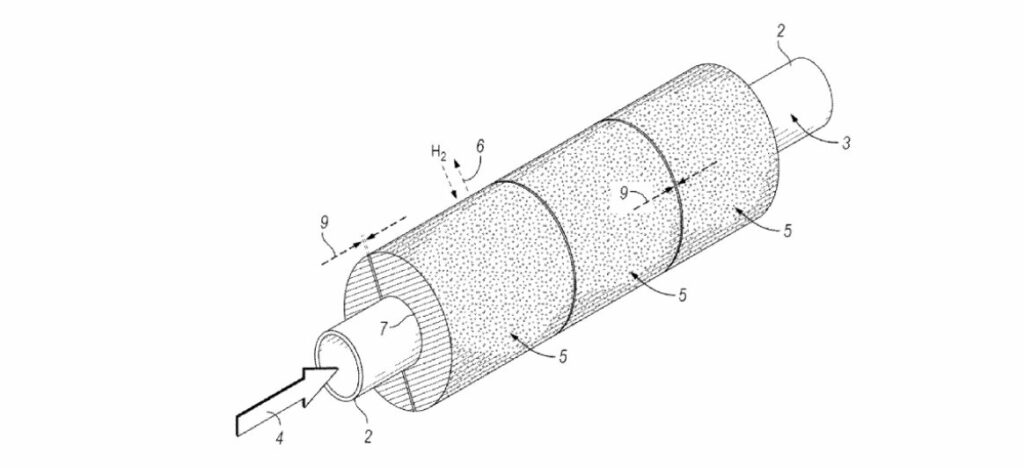

The patent proposes several innovative techniques for enhancing heat transfer between the metal hydride composite material and a heat exchanger:

Thermally Conductive Adhesive, Grease, or Solder

The use of thermally conductive substances like adhesive, grease, or solder between the metal hydride composite material and the heat exchanger is a key innovation. These materials bridge the gap between the two components, facilitating better heat conduction and thereby accelerating the rates of hydrogen absorption and desorption.

Snug Wrapping with Expanded Metal Sheath or Flexible Wire

Another technique involves snugly wrapping the assembly of metal hydride and heat exchanger with an expanded metal sheath or a flexible wire. This wrapping ensures tight contact, further promoting efficient heat transfer. The expanded metal sheath or wire acts as a conductive path, distributing heat more uniformly across the assembly.

Combination Approaches

The patent also suggests the possibility of combining these methods to further enhance the efficiency of hydrogen storage systems. By using both thermally conductive adhesives and snug wrapping techniques, the overall thermal management can be optimized, leading to even more significant improvements in system performance.

Implications and Future Prospects

This patent represents a step forward in the realm of hydrogen technology, particularly in improving the efficiency and practicality of hydrogen storage and compression systems. While it does not solve all the challenges associated with hydrogen energy, it addresses a crucial aspect that can make hydrogen a more feasible and attractive option for various applications.

The advancements outlined in Chevron’s patent have the potential to catalyze further innovations in hydrogen storage technology, contributing to the broader adoption of hydrogen as a clean and sustainable energy source. By focusing on enhanced heat transfer techniques, this patent paves the way for more efficient and practical hydrogen storage solutions in the future.