SK E&S has filed a patent on August 8, 2024, for an innovative expansion system aimed at improving off-site hydrogen charging stations.

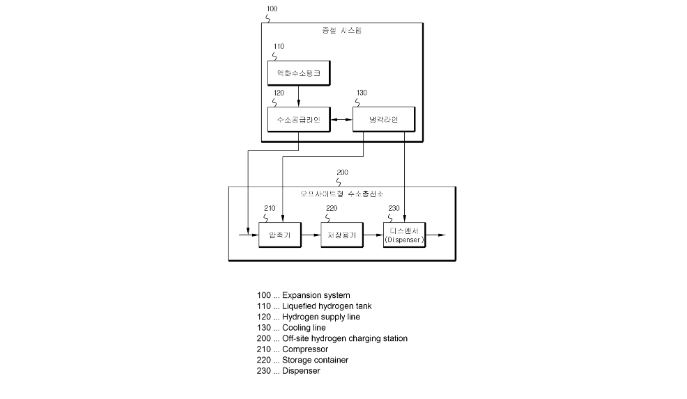

This system includes several key components: a liquefied hydrogen tank, a hydrogen supply line, and a cooling line, all designed to enhance the efficiency and reliability of hydrogen fueling stations.

Features and Improvements

The patented system offers substantial improvements over existing hydrogen charging technologies. The central innovation lies in its efficient use of liquefied hydrogen. The system’s hydrogen supply line not only vaporizes the stored liquefied hydrogen but also ensures it is delivered to the compressor at a controlled pressure. Additionally, the cooling line optimally uses the cold energy generated during vaporization to cool various pieces of equipment within the charging station. This dual-function approach enhances energy efficiency and reduces operational costs, distinguishing it from conventional systems that typically fail to utilize the cold energy effectively.

Potential Applications

The primary application of this technology is in off-site hydrogen charging stations, which are crucial for the hydrogen fuel cell vehicle (HFCV) industry. By integrating this expansion system, hydrogen stations can offer more consistent fuel availability and better cooling solutions for their equipment, leading to extended operational lifespan and reduced maintenance requirements.

Key technical aspects of the system include:

– Liquefied Hydrogen Tank: Stores hydrogen in its liquefied state, optimizing volume and storage conditions.

– Hydrogen Supply Line: Vaporizes liquefied hydrogen at a predetermined pressure before channeling it to the compressor.

– Cooling Line: Utilizes the resulting cold energy from hydrogen vaporization to maintain optimal temperatures for station equipment.

This integrated system approach highlights a well-coordinated method to enhance hydrogen fueling station performance, ensuring both efficiency and reliability.