F2N Green Hydrogen, an innovative start-up based in Varese, Italy, has completed internal qualification tests and the commercial launch of their CORNERSTONE alkaline stack product line.

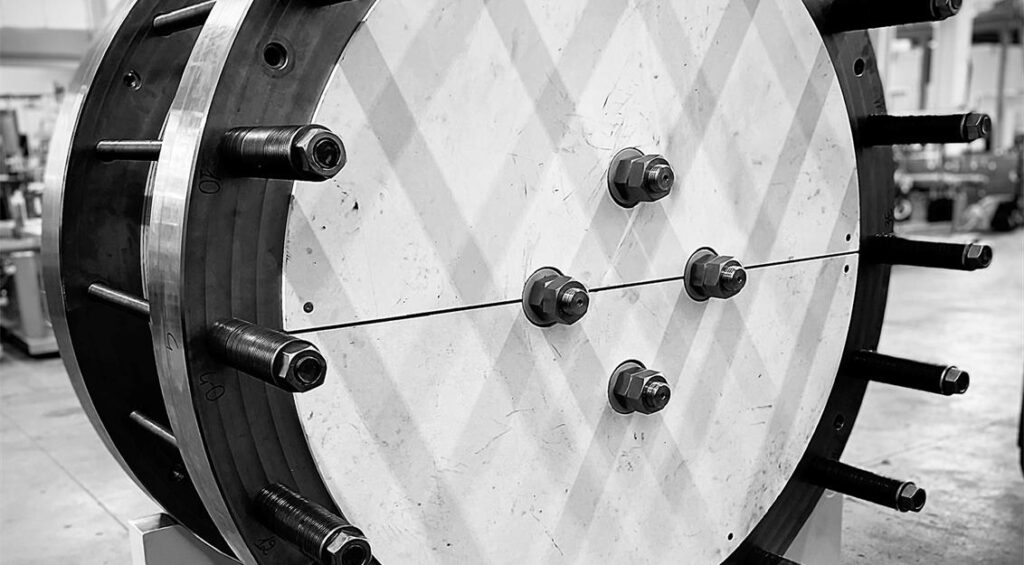

F2N Green Hydrogen’s CORNERSTONE stacks are designed for green hydrogen production at scale, offering a compact and efficient solution compared to existing technologies. The stacks have undergone qualification and characterization tests on a 500 kW prototype, representative of the product line extending up to 2 MW. These tests, including pressure equipment certification for up to 30 bar, are critical for ensuring the reliability and safety of the technology.

While F2N’s technological advancements are commendable, it is essential to compare them with industry standards. Leading players in the hydrogen sector, such as Siemens Energy and ITM Power, have already established themselves with robust and scalable electrolyzer solutions. Siemens, for instance, has developed the Silyzer 300, a large-scale electrolyzer with proven efficiency and reliability in various industrial applications. ITM Power’s PEM electrolyzers are also recognized for their high efficiency and ability to integrate with renewable energy sources.

In this context, F2N Green Hydrogen’s CORNERSTONE stacks must demonstrate not only their efficiency but also their cost-effectiveness and scalability to compete effectively. The start-up’s pilot plant and successful qualification tests are promising, but the real challenge lies in scaling up production and achieving commercial viability.

Green hydrogen is pivotal for achieving global climate goals, particularly in hard-to-abate sectors like heavy industry and transportation. F2N’s contribution to this value chain is significant, but it must be evaluated against the broader economic and environmental impact.

The efficiency of the CORNERSTONE stacks, coupled with their compact design, suggests potential reductions in both operational costs and carbon footprint. However, the cost of green hydrogen production remains high compared to fossil fuel-based hydrogen. For F2N to make a substantial impact, they need to address the economic viability of their technology. This includes reducing the cost of production, improving the durability of the stacks, and ensuring a reliable supply chain for the necessary materials.

With the successful completion of qualification tests, F2N Green Hydrogen is poised for the commercialization and industrialization phase. Francesco Massari, President and CEO, emphasized their commitment to providing innovative solutions for a sustainable future. This next phase involves not only ramping up production but also securing partnerships and customers in a highly competitive market.

Commercial success will depend on F2N’s ability to scale their operations efficiently and navigate regulatory frameworks across different markets. Moreover, establishing strong collaborations with industrial partners and stakeholders will be crucial for gaining market traction.