Recently, ROLLS-ROYCE filed a patent for an innovative gas turbine engine design that promises to enhance hydrogen fuel utilization, improve engine efficiency, and reduce emissions.

This patent describes a sophisticated system for optimizing the use of hydrogen fuel in gas turbine engines, primarily by making effective use of heat exchangers and compressor bleed air systems.

At the heart of this gas turbine engine is its core engine structure, which follows a sequential air flow series consisting of a compressor, combustor, and turbine. This standard configuration serves as the foundation upon which additional components operate to streamline hydrogen fuel usage.

A notable aspect of this patent is the innovative fuel offtake mechanism, which diverts a portion of hydrogen fuel from the main fuel conduit. This diverted fuel is subsequently burned in a specially designed burner. This not only allows for more precise control over fuel consumption but also aids in ensuring that the main fuel conduit remains efficient in distributing hydrogen fuel throughout the engine.

Crucial to this system is the heat exchanger that facilitates heat transfer from exhaust gases produced by the burner to the hydrogen fuel within the main conduit. This thermal exchange is vital for pre-heating the hydrogen fuel before it reaches the combustor, thereby improving the overall combustion efficiency and reducing the emissions associated with hydrogen fuel combustion.

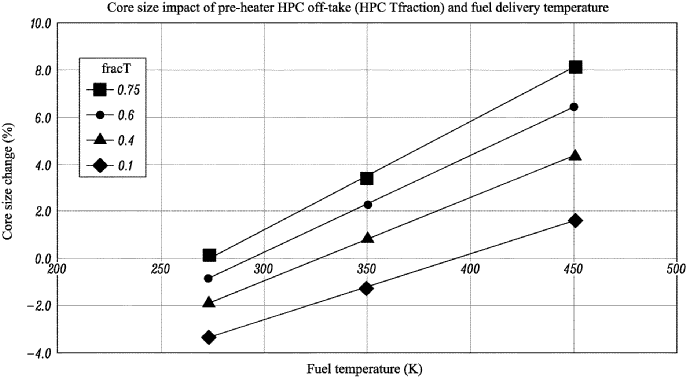

The engine design further incorporates multiple compressor bleed offtakes located at different pressure stages of the compressor. These offtakes are responsible for bleeding a portion of air from the compressor, which can then be directed to the burner. At each of these bleed stages, corresponding compressor bleed offtake valves manage the air flow, ensuring that the burner receives the appropriate amount of bleed air to maintain efficient fuel combustion.

By engineering a system that optimally manages the mix of hydrogen fuel and air within the turbine engine, this patent proposes significant contributions to improving environmental performance. The strategic use of hydrogen, along with enhancements in the thermal exchange process, enables the engine to minimize emissions while maximizing energy output.