Kobe Steel, Ltd., a prominent player in the industrial steel manufacturing sector, recently filed a patent for an advanced hydrogen gas compression unit. The patent, officially titled “Hydrogen Compressor Unit.”

Technological Features

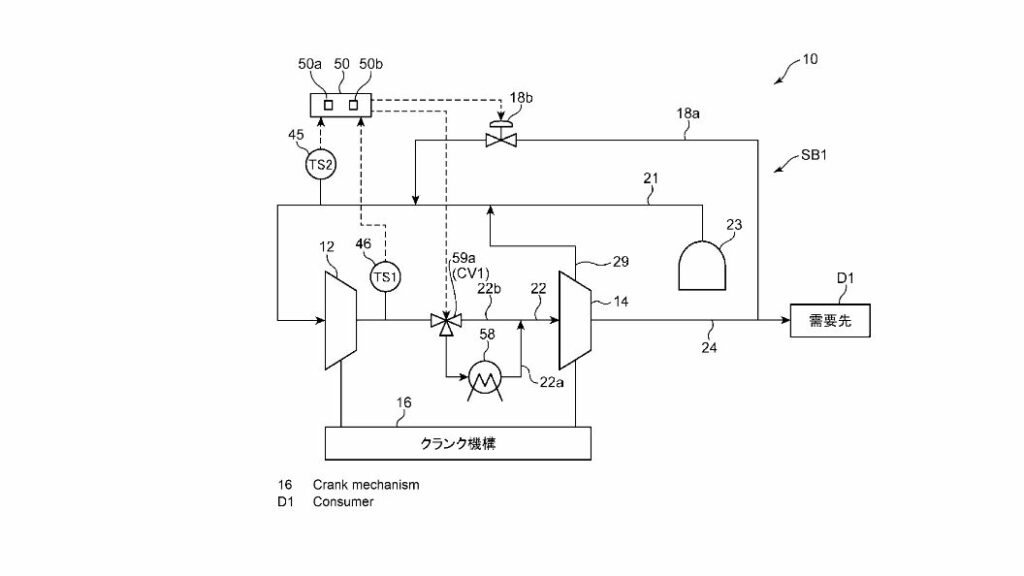

The patented compressor unit from Kobe Steel introduces several unique advancements to optimize hydrogen gas compression. A critical aspect of this technology is its intelligent temperature management system. A first switching mechanism operates under the control of a dedicated controller. This controller ensures that hydrogen gas bypasses the cooler when the temperature (TS1) recorded by the first temperature sensor is below a predefined threshold (T1).

Additionally, the system incorporates a second temperature sensor to monitor the suction temperature (TS2). If TS2 falls within a prescribed range—specifically, higher than a reference temperature based on the liquefaction temperature of air but below 0°C—the spillback valve adjusts accordingly. This mechanism ensures the system operates efficiently within safe temperature limits, optimizing the hydrogen gas compression process.

Potential Applications

The technology outlined in this patent has many applications, primarily in industries where hydrogen is a critical component. Potential applications include:

1. Fuel Cell Technology: Enhanced hydrogen compression may significantly boost the efficiency of hydrogen fuel cells.

2. Chemical Manufacturing: Industries that rely heavily on hydrogen for manufacturing processes, such as ammonia synthesis, could benefit from more efficient gas handling.

3. Hydrogen Refueling Stations: Improved compressor units will ensure faster and safer refueling of hydrogen-powered vehicles.

Market Impact

The introduction of this innovative compressor unit could substantially influence the hydrogen market. This technology promises to lower operational costs and enhance safety standards by offering more efficient temperature management and compression capabilities. As industries worldwide increasingly turn to hydrogen as a cleaner alternative fuel source, the demand for reliable and efficient compression solutions will likely rise, positioning Kobe Steel’s latest innovation as a significant contributor to this market shift.

Competitive Analysis

Compared to existing hydrogen compression technologies, Kobe Steel’s patented compressor unit stands out due to its advanced temperature management system. Traditional compression systems often require complex cooling mechanisms to operate safely and efficiently. Kobe Steel’s technology reduces reliance on expensive cooling processes by dynamically adjusting the flow and temperature of hydrogen gas based on real-time sensor data.

Technical Specifications

Some key technical features outlined in the patent include:

– First Temperature Sensor (TS1): This sensor detects if the hydrogen gas temperature is below the first threshold (T1).

– First Switching Means: Bypasses the cooler if TS1 is below T1.

– Second Temperature Sensor (TS2): This sensor ensures the suction temperature remains within a prescribed range conducive to efficient compression.

– Spillback Valve: Regulates the suction temperature based on TS2 readings.

Key Takeaways

Kobe Steel’s patent for a hydrogen compressor unit introduces a sophisticated method for optimizing hydrogen gas compression through dynamic temperature management. This technology presents a notable improvement over existing solutions by reducing the need for constant cooling and maintaining efficient operation within safe temperature ranges.

Compressor technology could play a pivotal role in elevating the operational efficiency and safety standards in various hydrogen-dependent industries, marking another step forward in the industrial application of hydrogen as a high-potential energy source.