Honda Motor Co., Ltd. has introduced a novel electrochemical hydrogen compression system in a patent titled “Electrochemical Hydrogen Compression System.” This patent, credited to Honda’s inventors, describes a sophisticated and efficient method for compressing hydrogen gas using a hydrogen compression stack and a refined control device.

Features and Improvements

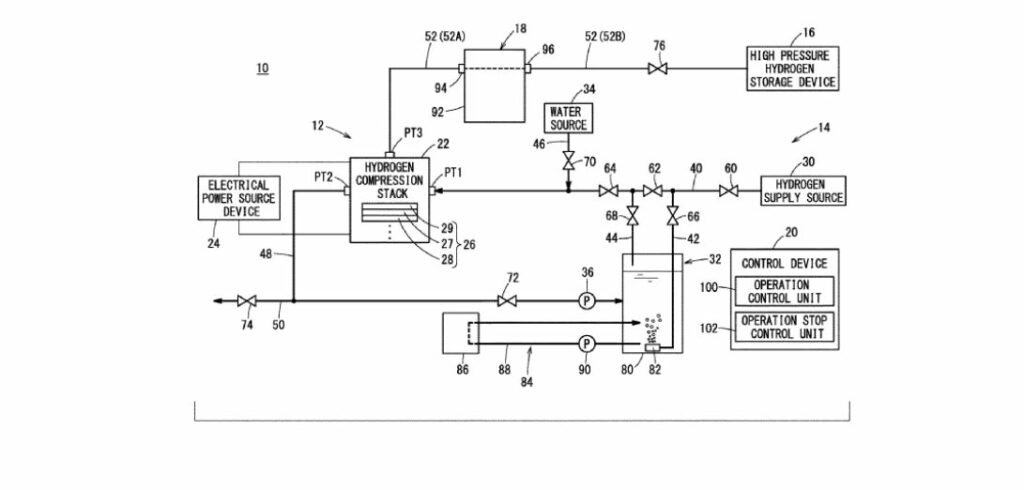

The patented system highlights two central units within its control device:

1. Operation Control Unit: This unit facilitates the hydrogen gas supply to the hydrogen compression stack while directing electrical currents from an electrical power source, initiating the compression operation.

2. Operation Stop Control Unit: This unit activates upon receiving a command to halt the operation. It first supplies liquid water to the hydrogen compression stack before continuing with the hydrogen gas supply, ensuring the system is safely and effectively managed.

This dual-unit configuration significantly improves existing hydrogen compression technologies, which often lack precise operational and safety controls. Introducing liquid water before hydrogen gas when stopping the compression process could reduce wear and enhance the durability of the hydrogen compression stack.

Potential Applications

The advanced hydrogen compression system has a range of significant applications, particularly in industries where efficient hydrogen compression is crucial. These include:

– Hydrogen Fuel Stations: Improving the speed and safety of refueling vehicles with compressed hydrogen.

– Industrial Hydrogen Storage: Providing a reliable method to compress and store hydrogen for various industrial applications, including chemical production and energy storage.

– Hydrogen Production Facilities: Enhancing the efficiency and management of hydrogen compression directly from electrolysis units or other production methods.

Market Impact

This innovation could substantially impact the hydrogen market by offering a more efficient, reliable, and safer method for hydrogen compression. As the demand for hydrogen, especially green hydrogen, continues to grow, technologies that optimize hydrogen handling will be critical. This system could lower operational costs, improve safety standards, and expand the adoption of hydrogen across various sectors.

Comparative Analysis

Compared to existing technologies, Honda’s electrochemical hydrogen compression system offers several distinct advantages:

– Enhanced Control: The dual-unit control device provides more rigorous management over the compression process.

– Safety Innovations: A liquid water supply during operational stops may prevent equipment damage and extend the system’s life.

– Efficiency Gains: By optimizing the compression process, this system may achieve better energy use and higher performance metrics than current market solutions.

Key technical components of the patented system include:

– Hydrogen Compression Stack: The core component where hydrogen gas is compressed through electrochemical means.

– Control Device: This device features the operation control and operation stop control units, ensuring precise and safe management of the compression process.

– Electrical Power Source Device: Provides the necessary electrical current to initiate and sustain the compression operation.

The “Electrochemical Hydrogen Compression System” patent by Honda Motor Co., Ltd. introduces a refined method for hydrogen compression that promises improvements in efficiency, safety, and durability. With applications across multiple industries and the potential to significantly enhance the hydrogen market, this innovation positions Honda as a notable player in the hydrogen economy. The main takeaway is the sophisticated dual-unit control device, which enhances operational safety and reliability and sets it apart from existing technologies.