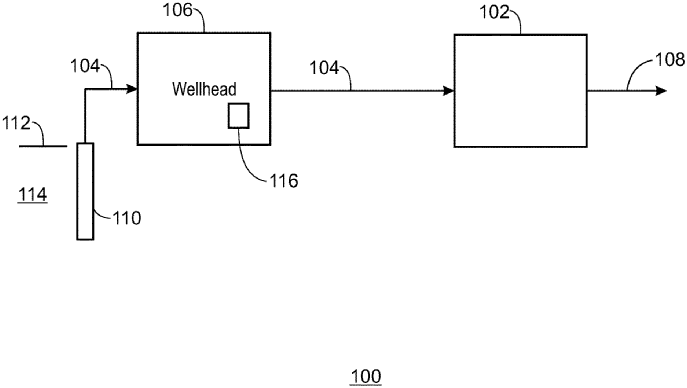

The patent focuses on a method to operate a natural gas processing plant that efficiently generates hydrogen gas as a by-product of the plant’s existing processes.

This patented technology introduces an integrated method to generate hydrogen gas during the natural gas processing cycle. The process involves the removal of acid gas, water, and non-methane hydrocarbons from incoming feed natural gas. The novel aspect of this technology lies in its use of blowdown water, a by-product of steam generation, which undergoes electrolysis to produce hydrogen gas. This generated hydrogen is then combined with the traditional fuel and combusted in the furnace to maintain the plant’s operational processes.

Potential Applications

The primary application of this patented technology is in the natural gas processing industry. The integration of hydrogen production within the natural gas processing workflow offers a dual benefit: producing a valuable green fuel while optimizing the utilization of resources within the plant. This method could be implemented in various natural gas processing plants worldwide, especially in regions focused on reducing carbon emissions and enhancing fuel efficiency.

This patent holds the potential to influence the hydrogen market significantly. By integrating hydrogen production into existing natural gas processing plants, companies can reduce reliance on traditional methods of hydrogen generation, which often involve high energy consumption and carbon emissions. This approach can also result in cost savings, given that it leverages an existing operational by-product (blowdown water) and minimizes additional resource expenditure.