Mitsubishi Heavy Industries, Ltd. has filed a patent that describes an advanced hydrogen production system and method. This innovative approach utilizes high-temperature steam electrolysis, significantly enhancing efficiency and sustainability in hydrogen production.

Core Components of the Hydrogen Production System

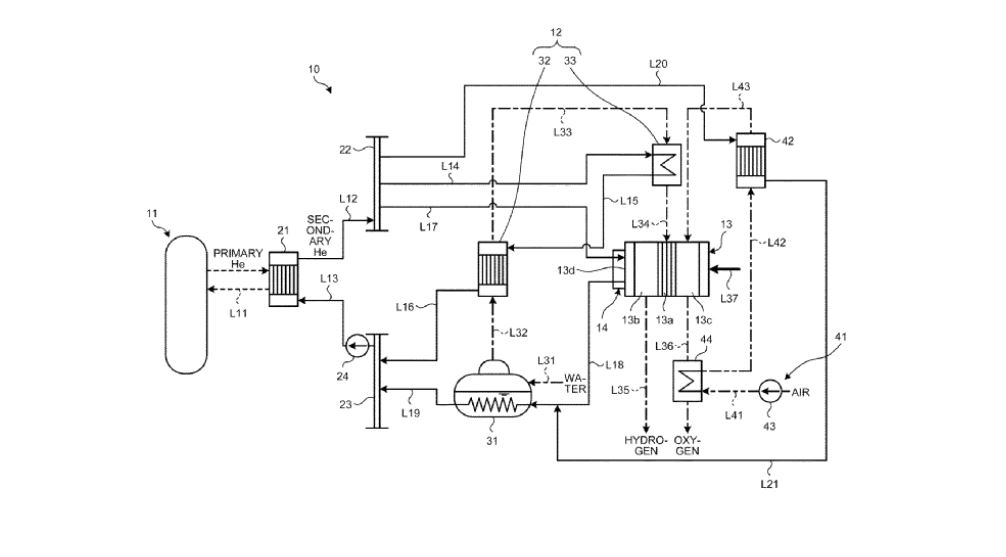

The proposed system consists of several crucial components:

– A heat source capable of generating thermal energy at 600°C or higher temperatures.

– A heat exchanger designed to heat steam using a heating medium warmed by thermal energy.

– A high-temperature steam electrolysis device that produces hydrogen using steam heated by the heating medium.

– A heating device designed to heat the high-temperature steam electrolysis using the thermal energy-heated medium.

Understanding the Heat Source and Heating Medium

A key element of this hydrogen production system is the heat source. The system requires a heat source consistently generating thermal energy at temperatures exceeding 600°C. By harnessing such high temperatures, the system can maximize the efficiency of the heat exchanger.

The heat exchanger plays a pivotal role by transferring the thermal energy from the heat source to the steam. This process elevates the steam’s temperature, making it suitable for high-temperature steam electrolysis.

High-Temperature Steam Electrolysis Device

The heart of this hydrogen production method is the high-temperature steam electrolysis device. This device facilitates the electrolysis process that produces hydrogen by using steam heated to optimal temperatures by the heat exchanger. The elevated temperature of the steam significantly improves the efficiency of hydrogen production.

The Role of the Heating Device

A heating device further heats the high-temperature steam electrolysis device to ensure it operates at its peak efficiency. This device uses the heating medium already warmed by the thermal energy, ensuring minimal energy loss and maximizing the overall efficiency of the hydrogen production process.

The Significance of Mitsubishi’s Innovation

While the significance of this patent should not be overstated, it marks a substantial step forward in hydrogen production technology. By integrating high-temperature steam electrolysis, the system promises enhanced efficiency and sustainability. This innovation could contribute significantly to cleaner energy solutions and the global effort to reduce carbon emissions.