Hydrogen has long been considered a clean and efficient energy source, with the potential to significantly reduce carbon emissions when used properly. In a bid to harness this potential, Mitsubishi Heavy Industries, has developed a revolutionary hydrogen production system that utilizes a Solid Oxide Electrolysis Cell.

This newly patented technology aims to make hydrogen production more efficient and sustainable. Here’s a detailed look into the innovative components and mechanisms that make up this system.

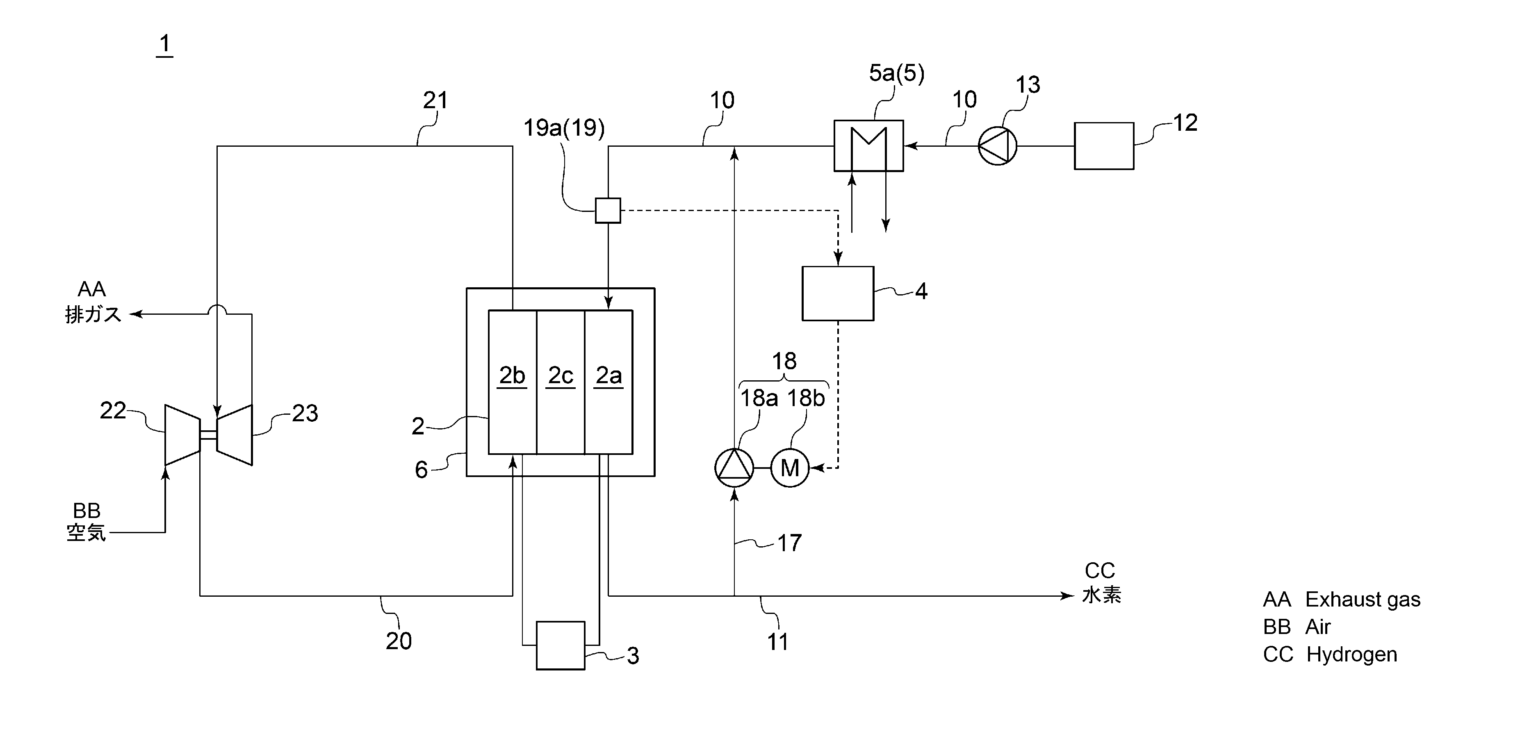

At the heart of this system is the Solid Oxide Electrolysis Cell (SOEC). SOECs are known for their high efficiency in converting water vapor into hydrogen and oxygen through electrolysis. Unlike traditional electrolysis, SOECs operate at high temperatures, which enhances their efficiency and reduces energy consumption. This makes the SOEC a key component in producing sustainable hydrogen.

A crucial part of the system is the water vapor supply line, which provides the necessary water vapor to the hydrogen electrode of the SOEC. Proper and consistent supply of water vapor ensures the continuous production of hydrogen. The design and functionality of this supply line significantly contribute to the overall effectiveness of the hydrogen production process.

Once the water vapor has been electrolyzed, the system needs a way to manage the discharged water vapor. This is where the water vapor discharge line comes into play. It circulates the water vapor that has been expelled from the hydrogen electrode, facilitating the flow and ensuring that the system operates smoothly. Proper discharge management is essential for maintaining the system’s efficiency and longevity.

In addition to the supply and discharge lines, the system features a first bypass line that links the water vapor supply line with the discharge line. This connection allows for the recirculation of water vapor, which helps in maintaining the right balance and pressure within the system. The bypass line plays a crucial role in optimizing the system’s performance by ensuring that excess water vapor is efficiently managed.

To ensure the proper functioning of the bypass line, the system includes a first regulation device. This device controls the flow rate of water vapor circulating through the bypass line, thereby fine-tuning the system’s operational parameters. By regulating the flow, the device helps in maintaining an optimal environment for electrolysis, ensuring consistent and efficient hydrogen production.