Hydrogen refueling stations play a critical role in the advancement of hydrogen as a clean fuel. Recently, a new patent titled “Hydrogen Refueling Station Based on Low-Temperature and High-Pressure Graded Hydrogen Storage,” developed by researchers from Zhejiang University, has introduced significant innovations in this field.

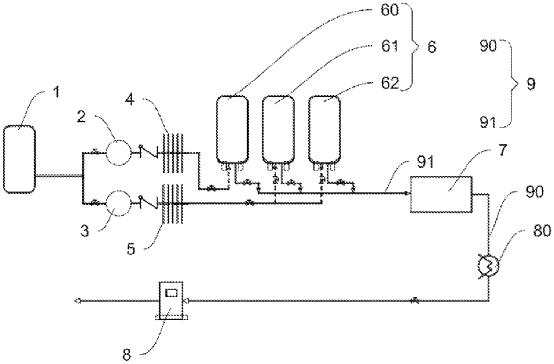

The hydrogen refueling station detailed in the patent includes several crucial components: a liquid hydrogen storage tank, multiple hydrogen storage vessels, a booster pump, and a high-pressure vaporizer. The storage vessels are designed to operate under low temperatures and high pressures, ensuring efficient storage and refueling processes.

The storage vessels maintain gaseous hydrogen at specific temperature and maximum pressure values, denoted as Tn and Pn. When the system includes two vessels (n=2), the temperatures and pressures are arranged such that T1 < T2 and P1 < P2. For systems with three or more vessels (n≥3), the temperature and pressure conditions follow a sequentially ascending order, e.g., T1 < T2 <… < Tn and P1 < P2 <… < Pn.

This arrangement optimizes the storage conditions and ensures effective utilization of hydrogen.

A main refueling pipe connects the hydrogen storage vessels with the hydrogen dispenser. This pipe is integral to the refueling process, facilitating the transfer of hydrogen from the storage vessels to vehicles or other hydrogen-consuming systems.

A sophisticated refueling controller manages the operation of the refueling station. This controller operates based on an ascending order of temperature values, sequentially directing the corresponding hydrogen storage vessels to communicate with the hydrogen dispenser. This orderly approach ensures an efficient and systematic refueling process.

The patent also introduces a novel gaseous hydrogen refueling method. The method involves managing the sequence and conditions under which hydrogen is dispensed from the storage vessels, further enhancing the efficiency and reliability of the refueling station.