In a pivotal development for the hydrogen industry, researchers Cong Qin, Zhanxiang Wei, Xiaoyan Zhao, Jianliang Cao, and Yan Wang have published findings on a novel high-temperature hydrogen sensor in the International Journal of Hydrogen Energy. This cutting-edge technology employs metal-organic frameworks (MOFs)-derived manganese-doped indium oxide (In2O3) hollow nanotubes, marking a significant advancement in hydrogen detection capabilities.

Relevance to the Hydrogen Industry

With the global shift towards hydrogen as a clean energy source, efficient and reliable hydrogen sensors are paramount. High-temperature environments, such as those in industrial processes and hydrogen fuel cells, require robust sensors capable of maintaining accuracy under extreme conditions. The research addresses this critical need, positioning itself as a key player in ensuring hydrogen technologies’ safe and effective deployment.

Key Findings

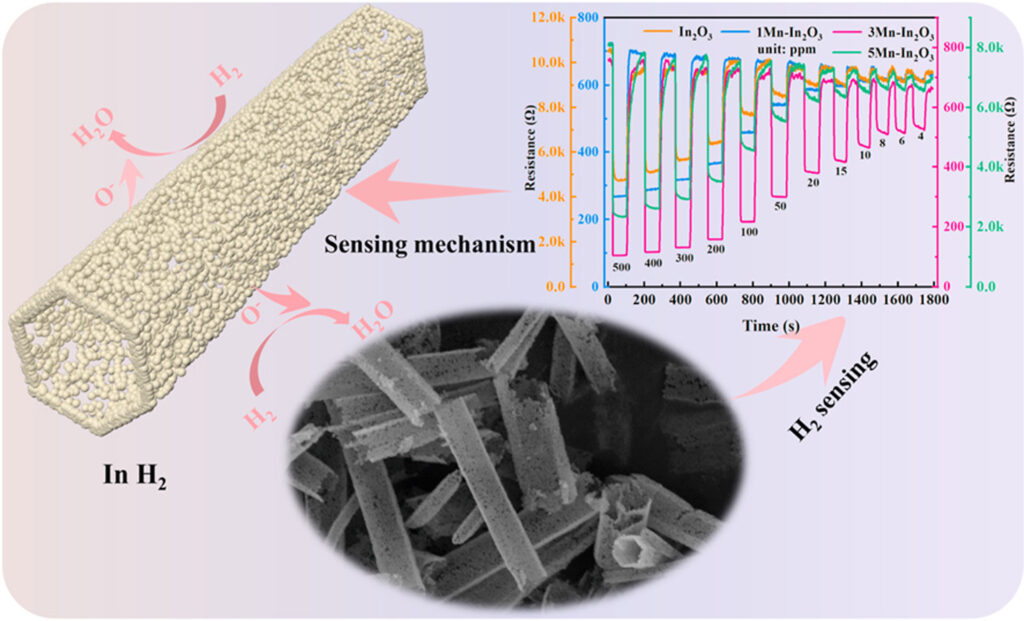

The study highlights the successful synthesis of manganese-doped In2O3 hollow nanotubes derived from MOFs. These novel sensors exhibit exceptional sensitivity and stability at high temperatures, overcoming limitations found in existing hydrogen sensor technologies. The researchers demonstrated the sensor’s ability to detect hydrogen concentrations accurately, even at elevated temperatures commonly encountered in industrial settings.

Applications and Market Relevance

This technology’s primary application is high-temperature hydrogen detection. Industries involved in hydrogen production, storage, and utilization stand to benefit greatly from this innovation. For instance, hydrogen fuel cell systems operate at high temperatures and require reliable sensors to monitor and manage hydrogen levels effectively. Similarly, hydrogen production facilities can enhance safety protocols with more accurate detection systems.

Technical Details and Methodologies

The research utilized metal-organic frameworks (MOFs) as a template to create hollow nanotubes of manganese-doped indium oxide (In2O3). This methodology endows the hollow nanotubes with a large surface area and enhanced reactivity, contributing to the sensor’s high sensitivity and stability. The doping with manganese further improves the conductivity and sensing performance at elevated temperatures.

Broader Implications for the Hydrogen Industry

The implications of this research extend beyond immediate applications. This innovation could catalyze further advancements in hydrogen technology safety and efficiency by addressing the challenges of hydrogen detection at high temperatures. Moreover, the successful integration of MOFs-derived materials in sensor development opens new avenues for research and development in other areas of hydrogen technology and beyond.

Key Takeaways

1. Researchers have developed a novel high-temperature hydrogen sensor using MOFs-derived manganese-doped indium oxide hollow nanotubes.

2. The sensor exhibits high sensitivity and stability at elevated temperatures.

3. Applications include hydrogen fuel cells and industrial hydrogen production, enhancing safety and efficiency.

4. The methodology leverages MOFs to create large surface area structures, improving sensor performance.

5. This advancement could spur further innovations in hydrogen technology and sensor development.

The development of this high-temperature hydrogen sensor marks a significant step forward in ensuring the safe and efficient utilization of hydrogen as a clean energy source. As the hydrogen industry grows, innovations such as this will play a pivotal role in shaping a sustainable energy future.