Modern renewable energy systems are constantly evolving, and a recent patent filed by the Dalian Institute of Chemical Physics, Chinese Academy of Sciences, offers an intriguing advancement in the field.

This innovative system and method for hydrogen production by water electrolysis is designed specifically for floating offshore wind turbines. The following subsections delve into the details, functionalities, and potential impacts of this novel invention.

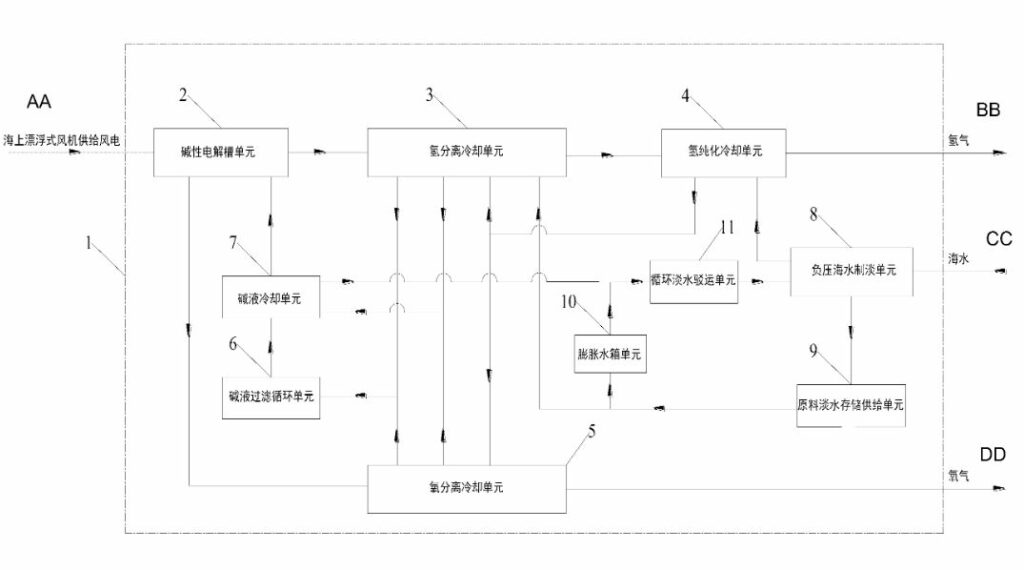

The hydrogen production system is ingeniously installed on the foundation of a floating offshore wind turbine. This strategic placement allows the system to utilize the electric energy generated on-site by the wind turbine for seawater electrolysis. By converting seawater into hydrogen, the system effectively integrates renewable energy with green hydrogen production, highlighting a significant step towards a sustainable energy future.

Core Components of the System

The system comprises various specialized units that work cohesively to produce hydrogen and manage resources efficiently. These include:

1. Alkaline Electrolytic Cell Unit

2. Hydrogen Separation and Cooling Unit

3. Hydrogen Purification and Cooling Unit

4. Oxygen Separation and Cooling Unit

5. Alkaline Solution Filtration and Circulation Unit

6. Alkaline Solution Cooling Unit

7. Negative-Pressure Seawater Desalination Unit

8. Raw Freshwater Storage and Supply Unit

9. Expansion Tank Unit

10. Circulating Freshwater Transportation Unit

Each component plays a crucial role in ensuring the system operates smoothly and optimally, contributing to an efficient hydrogen production process.

Closed Circulating Freshwater System

One of the standout features of this invention is the use of a closed circulating freshwater system as a cooling medium for the cooling units involved in hydrogen production by alkaline water electrolysis. This method not only optimizes the cooling process but also ensures that the absorbed heat is repurposed to power the negative-pressure seawater desalination unit. Consequently, the system achieves a closed freshwater circulation for heat transfer, which contributes to the self-sufficiency of freshwater.

Distributed Seawater Hydrogen Production

The applicability of this system to a distributed seawater hydrogen production scenario represents a key benefit. It enables the formation of a wind-power-hydrogen-freshwater one-stop device system, significantly enhancing the feasibility and efficiency of offshore green hydrogen production. This integrated approach aligns well with the ongoing global efforts to promote renewable energy sources and reduce carbon emissions.