The increasing demand for efficient and sustainable energy sources has propelled significant advancements in hydrogen technology. Among the innovations is the liquid hydrogen storage tank ZBO (Zero Boil-Off) system.

The patent, titled “Liquid Hydrogen Storage Tank ZBO System,” filed by the Korea Institute of Machinery & Materials, presents a novel approach to controlling temperature and pressure within a storage tank utilizing a specialized system.

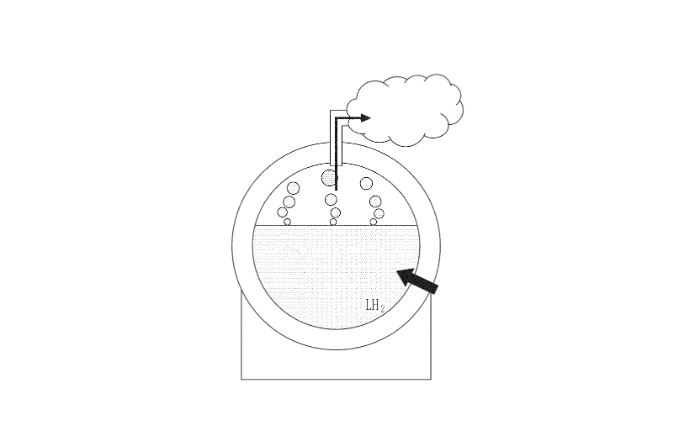

Storing liquid hydrogen poses unique challenges, predominantly due to its extremely low boiling point. Managing temperature and pressure efficiently is crucial to minimize losses from boil-off, ensuring storage safety and efficiency. Traditional methods often struggle with delays in temperature regulation, leading to inefficiencies and increased operational costs.

The ZBO System Solution

The patented ZBO system introduces an innovative solution to effectively control the temperature and pressure within a liquid hydrogen storage tank. This is achieved through a sophisticated mechanism that involves rapid operation of a refrigerator system.

Central to this technology is the use of an infrared sensor. A sensor pad is strategically attached to the outer surface of the storage tank. This sensor is integral in measuring heat flux, which is the rate of heat energy transfer through a given surface. By accurately measuring this heat flux, the system infers any delay in temperature changes, allowing for swift corrective actions.

Accompanying the infrared sensor is a calculator, designed to process the data. This device calculates a heat flux value using information from the sensor pad, providing precise data on the temperature dynamics within the storage tank. The calculated heat flux value is crucial for making real-time adjustments.

The ZBO system also includes a controller tasked with managing the operation of a refrigerator. By utilizing the heat flux data, this controller ensures that the refrigerator operates swiftly and efficiently. This enables real-time adjustments in temperature and pressure, reducing the risk of boil-off and preserving the stored hydrogen.

Stay updated on the latest in energy! Follow us on LinkedIn, Facebook, and X for real-time news and insights. Don’t miss out on exclusive interviews and webinars—subscribe to our YouTube channel today! Join our community and be part of the conversation shaping the future of energy.