The patent titled “Method for Starting a Fuel Cell System” presents a step-by-step procedure to efficiently initiate a fuel cell system, designed by the reputable Robert Bosch GmbH.

Filed on October 10, 2024, this innovation aims to optimize the startup process of fuel cell systems, ensuring reliability and performance.

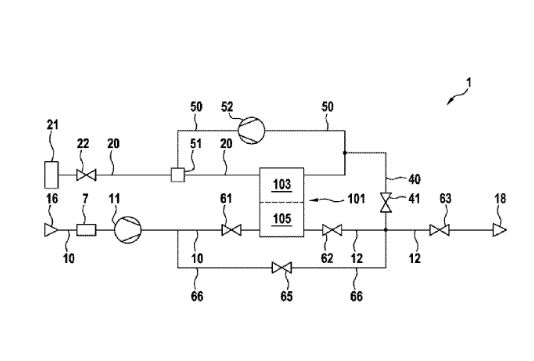

A fuel cell system consists of different components: a fuel cell stack, an air path, an exhaust gas line, and a fuel line with a recirculation circuit. These components need to interact seamlessly to enable the fuel cell system to start effectively. The process outlined in this patent aims to enhance this interaction.

The startup method involves a series of systematic steps to prepare and initiate the fuel cell system for operation:

1. Initial Preparations

Before starting the process, the system requires the closure of two critical valves: one in the air line and one in the exhaust gas line. This ensures the system is in a stable state before initiating the air compactor.

2. Activation of the Air Compactor

The process begins with starting an air compactor in the air path. This step is vital to ensure that the necessary air pressure is built up to support the fuel cell operation.

3. Pressure Regulation

The method includes throttling a pressure controller in the exhaust gas line to generate a pressure exceeding 1.5 bar. This pressure setup is crucial for maintaining optimal conditions within the fuel cell system.

4. Valve Operations

The next steps involve precise control over the valves. After flushing the anode with hydrogen, either the first or second valve is opened. This action allows for initial air or hydrogen flow, creating the right environment for the fuel cell to start.

5. Bypass Valve Adjustments

Adjusting the bypass valve’s flow is another critical step, leading to control over the internal circulation within the system and preparing it for further operations.

6. Synchronization of Valves

Both the first and the second valves are opened eventually, allowing for a simultaneous flow throughout the system. This step sets the stage for full integration of the components.

7. Final Pressure Adjustment

The method concludes with dethrottling the pressure controller, ensuring the pressure in the exhaust gas line meets the target level necessary for a successful startup.